What are the common heat treatment processes for melt pump gears?

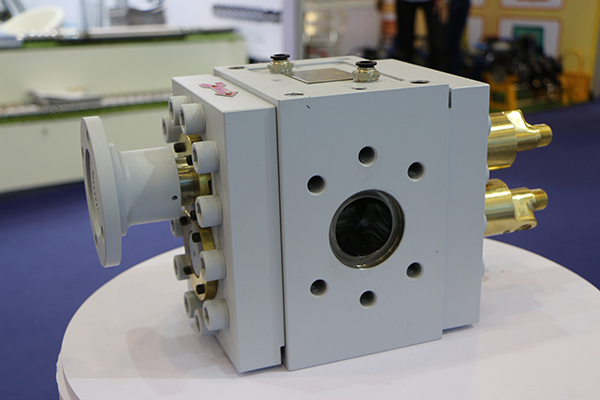

BATTE is a melt pump manufacturer in Zhengzhou, Henan, China. It provides special extrusion melt pumps for the domestic plastic and rubber extrusion fields. Years of experience in melt pump R&D and production have been recognized and feedbacked by many domestic and foreign customers; Batte has Professional processing equipment and advanced processing technology, each melt pump equipment provided has high standards and high performance. The gear of the melt pump is a vulnerable component and the core component of the high temperature melt pump extrusion, which is very important for the efficient production and operation of the melt pump. Batte hot melt pump manufacturers specifically analyze and explain the common heat treatment process of gears. Different processing technology, it is applied to different material conveying. The melt mainly conveyed by the melt pump for plastics is corrosive, strong acid, etc. Therefore, the pump body and gear of the melt pump need to be made of alloy steel or stainless steel, such as Cr12MoV, W18Cr4V and W9Cr4V2, etc.

Generally, the gears and shafts (or gear shafts) of high temperature melt pumps are mostly Cr-Mo alloy steels with high hardenability, hardened or nitrided tool steels and similar special steels. Its heat treatment usually has the following methods:

1. Surface hardening treatment, such as nitriding, carbonitriding, etc. Has good torque transmission characteristics and is not prone to breakage under high load conditions. However, due to the large difference between the hardness of the metal surface and the interior, it is easy to cause the extrusion damage of the hard metal to the soft metal layer.

2. Hardening type treatment. It has good wear resistance and will not cause the entire gear to fail quickly due to the damage of the surface layer. The disadvantage is that the harder the gear, the more likely it is to break, and it is sensitive to torque and vibration. After hardening treatment, the surface is hardened. It not only avoids too much difference in hardness between the metal surface and the inner layer, but also has strong resistance to surface damage and excellent torque transmission performance. This is one of the preferred heat treatment options.

In the gear heat treatment method of melt gear pump, domestic chemical melt pump manufacturers usually adopt the method of whole body quenching, the hardness is kept at HRc54-58, the surface is titanium nitriding, and the hardness reaches Hv2500, so as to ensure the internal hardness and internal surface hardness. Corrosion resistance and wear resistance, better pitting corrosion resistance than pure nitriding tooth surface. Learn more about the relevant melt pump price or quote info@battemachinery.com