High temperature and high pressure melt pump parameters at a glance

The following is an introduction to the common parameters of high temperature and high pressure melt pump:

First, the temperature parameters

Use temperature: In general, the high temperature and high pressure melt pump's usually in 300 ℃ -350 ℃ or so. Some special material pumps can be used up to 510 ℃.

Cleaning temperature: cleaning temperature is usually higher than the use of temperature, generally between 450 ° C - 590 ° C, to ensure that the pump can be completely removed from the residual material.

Second, the pressure parameters

Inlet pressure: the inlet pressure is generally in the vacuum (-0.05 ~ -0.08mpa) to 30Mpa between the change, usually 3-5Mpa can meet most of the working conditions, but high viscosity fluid may require higher inlet pressure, and sometimes in order to enhance the mixing of the melt in the extrusion screw, it will also be appropriate to adjust the inlet pressure.

Outlet pressure: The outlet pressure can be from 0 to 40Mpa, some special working conditions require high outlet pressure, such as H series high temperature and high pressure melt pumps outlet pressure can be up to 50Mpa, which can satisfy the demand.

Differential pressure: the differential pressure of common melt pump can reach 20Mpa, and the differential pressure of high pressure resistant melt pump can reach 35Mpa.

Third, the flow parameters

specifications and flow range: melt pump specifications from small to large there are a number of levels, the flow range from 0.05cc to 30,000cc ranges, common specifications are 1cc, 2cc, 5cc, 10cc, 20cc, 31. 5cc, 50cc, 100cc, 150cc, 200cc, 315cc, 500cc, 800cc, 1200cc, 2500cc and so on.

Flow stability: high temperature and high pressure melt pump in high viscosity and high pressure flow stability, no outlet pressure fluctuations, to ensure that the melt in the delivery process to maintain a stable flow, thus ensuring the stability of production and product quality.

Fourth, the viscosity parameters

high temperature and high pressure melt pumps can handle a wide range of medium viscosity, generally between 1 to 4000pa・s (1000 to 4,000,000cp), and even up to 20,000Pa・s, to meet a variety of high-viscosity fluid transportation needs.

Fifth. Material parameters

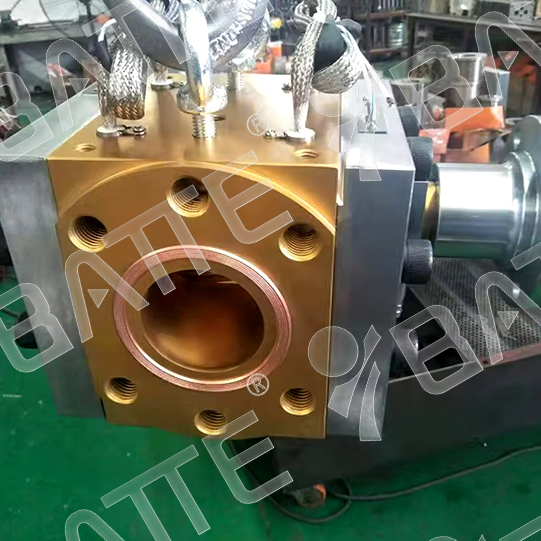

Pump body material: common tool steel, nitrided steel, stainless steel, alloy steel, etc., these materials have the characteristics of high temperature resistance, abrasion resistance, corrosion resistance, etc., which can ensure the stable operation of the pump body in high temperature and high pressure environment.

Gear material: tool steel, titanium-tantalum alloy, Hastelloy, imported tool steel, nitrided steel and other materials, and can provide a variety of material options according to different conditions and customer needs to ensure that the strength of the gear, abrasion resistance and corrosion resistance.

Bearing materials: generally tool steel, stainless steel + coating, corrosion-resistant alloys, etc., with good wear resistance and corrosion resistance, and can adapt to the high temperature and high pressure working environment.

Shaft seal material: commonly used shaft sealing methods are spiral mechanical seal, packing seal, combined seal, etc. The shaft seal material should have good sealing performance and high temperature resistance to prevent melt leakage.

Sixth. Other parameters

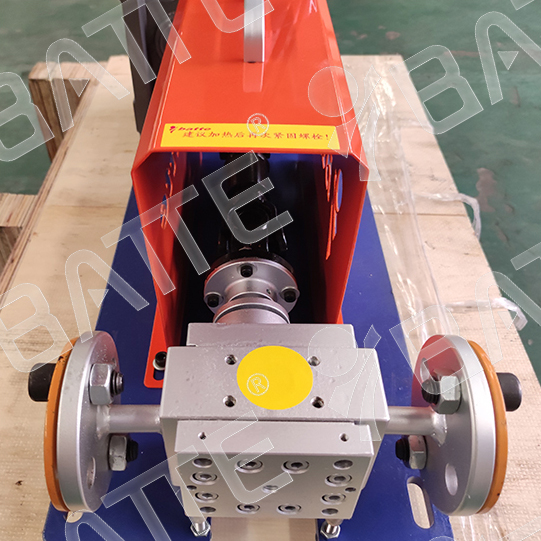

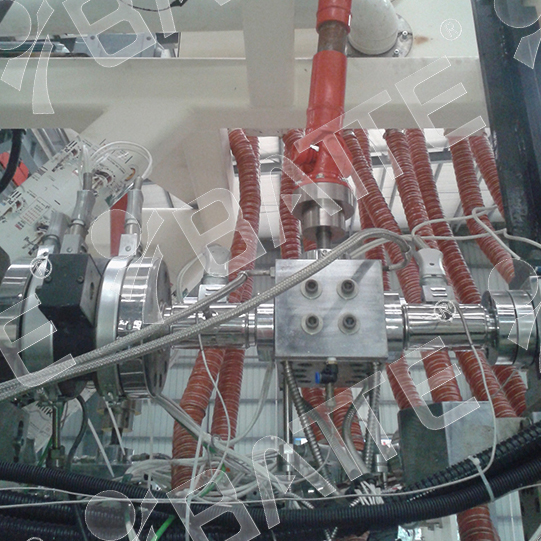

Heating: electric heating or thermal media heating can be used, small and medium-sized melt pumps generally use electric heating, large melt pumps can be jacketed pump body with fluid temperature control and other ways.

Installation: common installation methods are horizontal installation, vertical installation (up and down can be), and according to the customer's different on-site conditions to provide the appropriate installation, but also to ensure that the pump seat and the motor drive shaft concentricity, in order to ensure that the pump's normal operation.

Precision: The precision of the pump body can generally reach ±0.5%, high precision manufacturing and excellent heat treatment process, making the melt pump more precise, durable, and able to meet the requirements of precision extrusion and other high-precision production processes.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071