PET sheet extruder melt pump technical characteristics and application advantages

First, sheet extruder melt pump technical characteristics

Wide viscosity range: PET material viscosity will change under different processing temperatures and conditions, and the melt pump can adapt to PET melt transportation from low viscosity to high viscosity, with a wide range of viscosity, generally 1~40,000pa・s, which can meet the needs of different stages and formulations in the production process of PET sheet.

High-temperature and high-pressure adaptability: The extrusion of PET flakes is usually carried out under high temperature and pressure, and the melt pumps are able to operate stably under high-temperature (general operating temperature ≤350℃) and high-pressure (output pressure of 0~40mpa) conditions to ensure the effective transportation of PET melt and extrusion molding.

Optimized flow channel design: Its flow channel design has been optimized to eliminate dead corners in the flow channel, which can reduce the polymer residue to the minimum, avoiding the impact of residual substances on the quality of PET flakes, and improving the purity and appearance quality of the products.

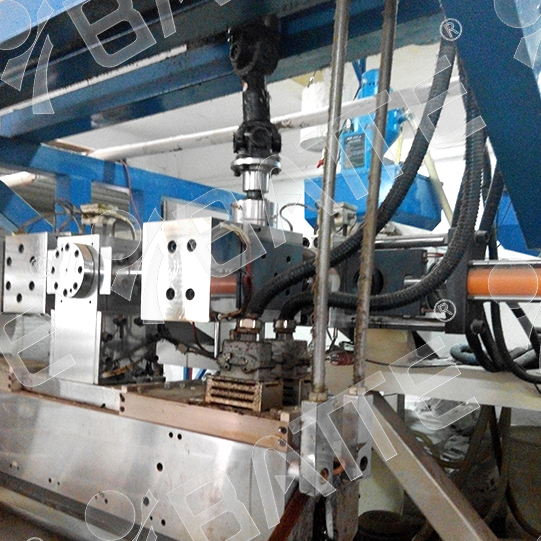

A variety of installation methods: In order to meet the layout of production equipment and individual needs of different users, PET sheet extruder melt pump provides a variety of installation methods, which is convenient to be installed and connected with a variety of models and specifications of extruders, molds and other equipment.

Second, sheet extruder melt pump application advantages

Improve product quality: it can effectively improve the dimensional accuracy, thickness uniformity and surface quality of PET sheet, reduce bubbles, impurities and other defects, so that the performance of the sheet is more stable and reliable, to meet the stringent requirements of high-end applications on the quality of PET sheet, such as electronics, optics, food packaging and other industries.

Reducing production cost: on one hand, through the stable working condition and precise metering control, it reduces the scrap rate and the waste of raw materials; on the other hand, it reduces the load of the extruder and saves energy consumption, which reduces the production cost of PET sheet to a certain extent.

Convenient production management: Its stable performance and precise control function make the production process easier to manage and control, reduce the difficulty of production adjustment and quality monitoring caused by fluctuation of equipment parameters, improve the stability and operability of production, and help enterprises realize large-scale and standardized production.

Adapt to a variety of production processes: Whether it is single-layer PET sheet extrusion, or multi-layer co-extruded PET sheet production, melt pumps can play to its advantage, adapting to the requirements of different production processes, which provides enterprises with more flexible production options, and helps to develop diversified PET sheet products.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071