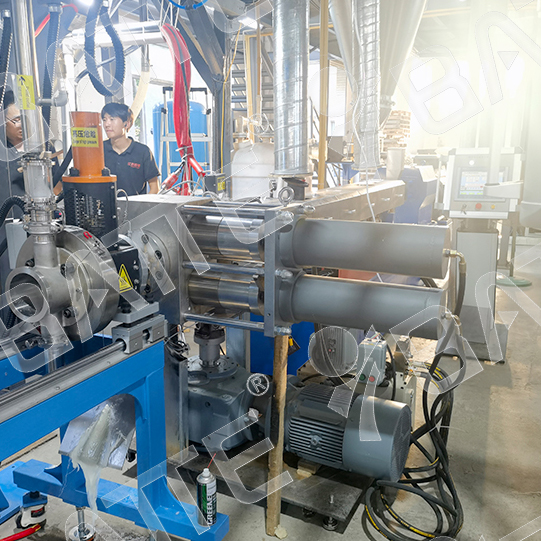

Twin-screw extruder melt pump

Twin-screw extruder melt pump stabilizes the delivery of melt through precision gear design, enhances extrusion pressure and metering accuracy, significantly improves product quality and production efficiency, and is the core equipment for plastics, rubber and other industries.

1, role and function:

Melt pump in twin-screw extruder mainly plays the role of stabilizing melt delivery, improving extrusion pressure and accurate metering.

It helps to maintain a constant melt pressure during the extrusion process, thus improving the quality and consistency of the extruded products.

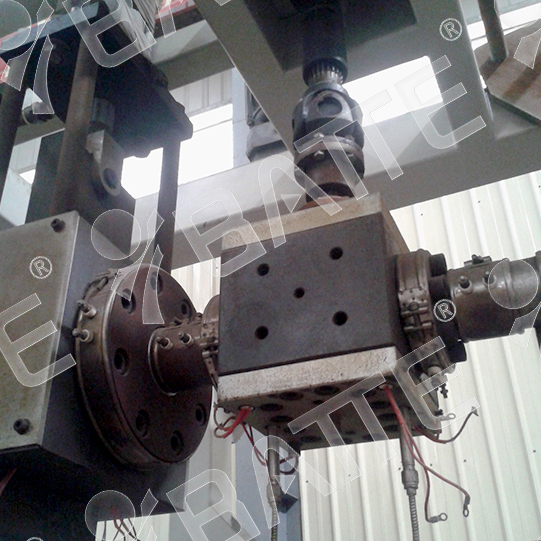

2. Structural characteristics:

Twin-screw extruder melt pumps are usually designed with precision gears to ensure stable melt delivery and accurate metering.

The pump body is compact and resistant to high temperature and high pressure, which can adapt to the harsh working environment.

3, Advantages and applications:

Twin-screw extruder melt pump has the advantages of high efficiency, stability, accurate metering, etc. It is widely used in the extrusion line of plastic, rubber, chemical fiber and other industries.

It can improve production efficiency, reduce production costs, and at the same time enhance the quality and competitiveness of extruded products.

4, maintenance and repair:

Regularly check and maintain the melt pump, including cleaning, lubrication and replacement of worn parts, etc., to ensure its long-term stable operation.

Pay attention to avoid the melt pump extrusion running under overload or abnormal working conditions to prevent equipment damage or safety accidents.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071