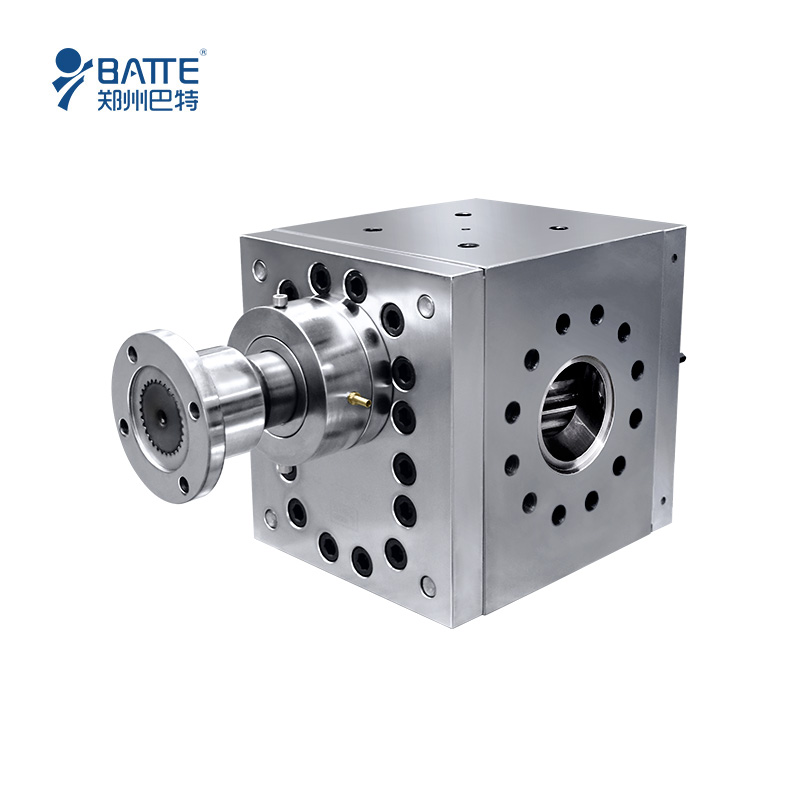

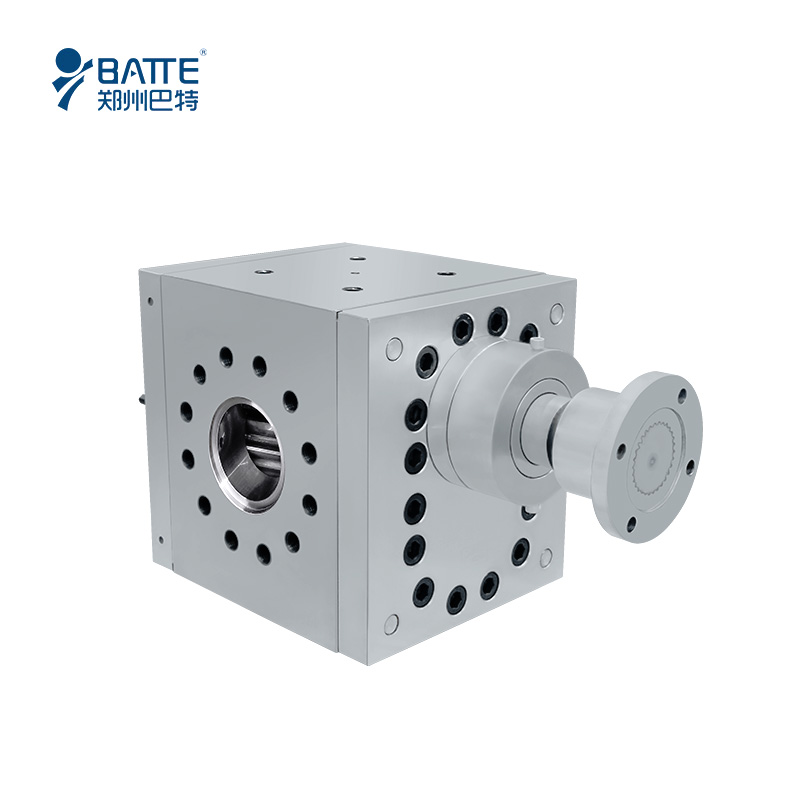

batte melt pump extrusion

the role of Melt pump extrusion

The main function of the melt pump extrusion is to pressurize the high-temperature plastic melt from the extruder. After the pressure is stabilized, the flow rate is steadily fed into the extruder head. Its ability to stabilize melt pressure and flow is superior to all types of extruders. When it is used in series with a single screw or co-rotating twin screw extruder, the benefits of the entire production line are significantly increased. The main benefits of applying a melt pump are:

1. To minimize the dimensional tolerance of the extruded product, make more weight per unit weight of the product. The use of melt pumps is even more necessary and valuable when the dimensional tolerances on the extruded product are critical or the raw material cost of the product is more expensive.

2. The same direction twin-screw extruder and melt pump combination into extrusion extrusion granulation production line, the mixing quality and yield than a single twin-screw granulation unit substantially increased. Energy consumption per kilogram of material can generally be reduced by about 25%.

3. melt pump extrusion In the original is a single screw or co-rotating twin-screw granulation extruder with melt pump and pipe, plate, film extruder head, granulation process can be omitted direct extrusion products. This system is ideally suited for blends where the material needs to be blended and modified. The melt pump system, in addition to the above advantages of the second, but also by simplifying the production process of extruded products, shorten the production cycle to achieve energy saving.

4. Melt pump extrusion can be achieved with more than one small and medium-sized extruder to a melt pump feed, melted melt pump pressurized metering head extrusion large products (large-diameter pipe, wide Board, film, etc.). This configuration of the production line compact structure, small footprint; extruded product cross-sectional size is more accurate and easy to control.

5. In the single-screw exhaust extruder melt pump configuration, the system can operate freely, excellent performance. In the high head pressure and high yield, the amount of extrusion can be adjusted and no risk of free-take situation.

|

Pump Model

|

Pump Volume (CC)

|

Driven Power (kw)

|

Heating Power (kw)

|

Working Temperature

|

Working Pressure

|

|

ZB-0.6

|

0.6

|

0.37

|

0.5

|

≤400℃(750°F)

|

Outlet Pressure: ≤ 40Mpa(6,000psi)

Outlet Differential Pressure: ≤ 275Mpa

|

|

ZB-1.2

|

1.2

|

0.75

|

0.5

|

|

ZB-2

|

2

|

0.75

|

1

|

|

ZB-5

|

5

|

1.1

|

2

|

|

ZB-10

|

10

|

1.5

|

2

|

|

ZB-20

|

20

|

2.2

|

2

|

|

ZB-31.5

|

32

|

3

|

2

|

|

ZB-50

|

50

|

4

|

3

|

|

ZB-100

|

100

|

5.5

|

4

|

|

ZB-150

|

150

|

7.5

|

5

|

|

ZB-90/90

|

200

|

11

|

6

|

|

ZB-100/100

|

250

|

15

|

8

|

|

ZB-100/100

|

315

|

18.5

|

8

|

|

ZB-115/115

|

500

|

22

|

12

|

|

ZB-130/130

|

800

|

30

|

15

|

|

ZB-160/160

|

1200

|

37

|

20

|

|

ZB-180/160

|

2500

|

45

|

24

|

|

ZB-180/180

|

3200

|

55

|

24

|

|

ZB-224/224

|

6000

|

75

|

30

|

Email: info@battemachinery.com

Whatsapp: +86 158 38331071