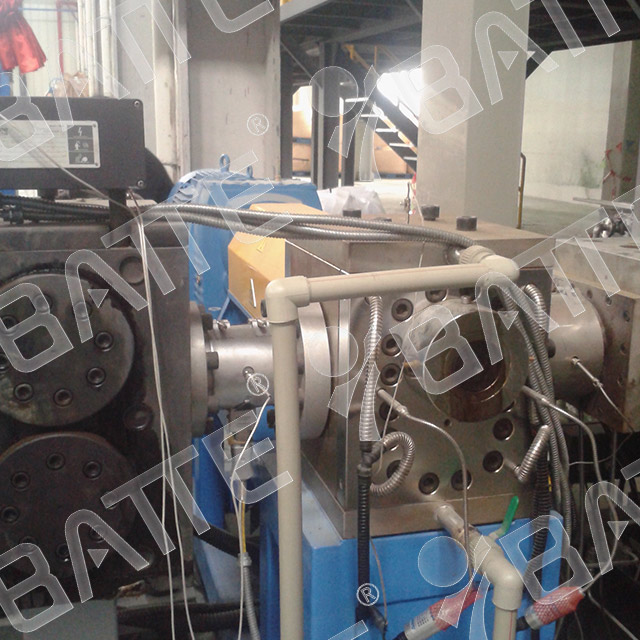

Melt pump extrusion for blown film pipes and thin films

Introduction to Pelletizing chemical melt pump

Melt booster pumps are widely used in the extrusion molding of plastic, resin, rubber, and chemical fiber products, such as granulation, film, pipe, plate, sheet, artificial fiber, optical fiber, medical plastic conduits, and other industries.

Working principle of melt booster pump

The melt booster pump relies on the change in working volume caused by the mutual meshing of the master and slave gears to transport the melt. When the gear rotates in the specified direction, the melt will enter the middle of the grooves of the two gears in the feeding area. Then, the gear starts to rotate, and the melt is brought into the feeding area from both sides. The gear teeth again, allowing the melt in the grooves to be squeezed out of the discharge area and sent to the outlet pipeline. As long as the pump shaft rotates, the gears pressurize and transport the melt to the outlet, so the pump outlet can reach a high pressure without requiring too high inlet flow and pressure.

Material of melt pump extrusion

Pump casing: stainless steel/alloy steel/corrosion-resistant alloy

Gears: Nitrided steel/Tool steel/Stainless steel+Coating/Corrosion resistant alloy

Bearings: tool steel/copper alloy/stainless steel+coating/corrosion-resistant alloy

Technical parameters of blown film melt pump

1. Transmission medium viscosity: 100-400000cP

2. Suction pressure: Vacuum (-0.00~-0.05MPa)~16MPa

3. Output pressure: 0-35MPa

4. Operating pressure difference: 25MPa

5. Operating temperature: ≤ 350 ℃

6. Heating method: heat medium jacket

7. Heating medium pressure: ≤ 1.6MPa

Installation method of hot melt pump

The extrusion melt pump is driven by an electric motor, reducer, and universal coupling. The melt booster pump belongs to a positive displacement forced delivery pump, and the pump output flow can be adjusted by adjusting the pump speed. It is recommended to use a frequency conversion speed control method to achieve near linear flow output of the gear pump.

Manufacturer of melt pump for extruder

The polymer melt pump provided by the company has the characteristics of precise structure, high accuracy, small pressure and flow pulsation, and long service life. The company also provides full process services such as consultation, design, surveying, maintenance, renovation, and spare parts for melt pumps, which can meet your different needs. Welcome to consult.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071