The state of sliding bearings affects the working efficiency of melt pumps

The working state of the sliding bearing of the polymer melt pump should be such that a relatively uniform liquid film can be formed between the driving shaft and the inner surface of the sliding bearing. This liquid film can completely separate the two metal surfaces of the shaft and the sliding bearing, and the liquid film will play a role in supporting the shaft load. When the melt pump for extrusion stops running, the journal will be located at the lower part of the sliding bearing, with two metal surfaces in direct contact. The gap between the shaft and the bearing is not lubricated by the melt. At the beginning of startup, the bearing is in dry friction.

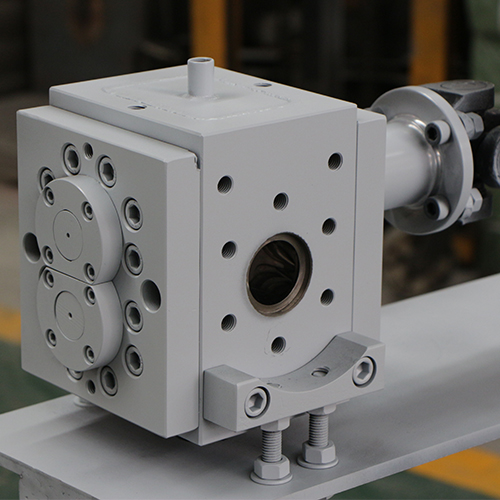

melt pump for extrusion

As the amount of molten material transported increases and the outlet pressure gradually increases, under the effect of the pressure difference between the outlet and inlet, some of the molten material enters the bearing gap through the guide groove. As the shaft rotates evenly, a thin film formed by the molten material forms on the surface of the shaft and bearing. At this time, the friction force between the two metal surfaces gradually decreases. When the melt film fully supports the vertical load of the rotating shaft, the frictional resistance of the bearing is only the viscous resistance of the melt. At this point, close to the liquid lubrication state, the friction coefficient of the two metal surfaces will reach an ideal state. Therefore, it is impossible to achieve an ideal lubrication state under limited load.

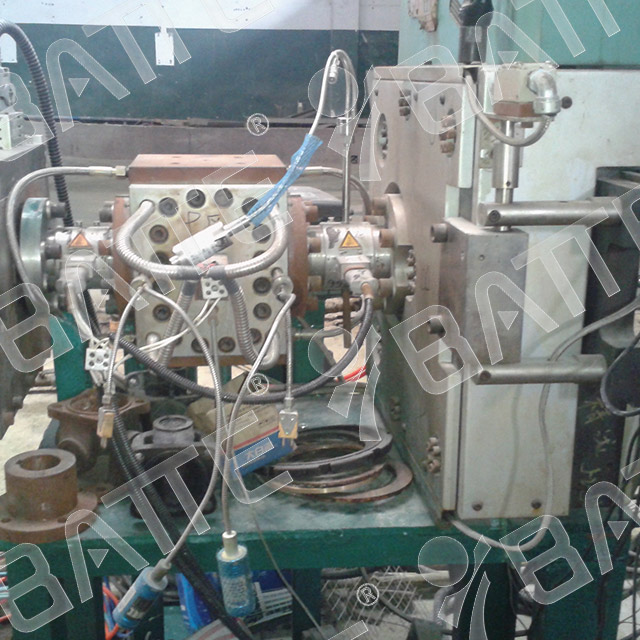

melt gear pump in extruder

The failure forms of sliding bearings are mainly abrasive wear and adhesive wear. The higher the outlet pressure of the melt gear pump, the greater the shear force of the shaft on the lubricating film, and the more severe the damage to the lubricating film. The bearing area is closer to mixed friction, and sometimes even in a dry friction state, which causes more severe damage to the driving shaft and bearing surface. When the wear on the inner surface of the shaft and sliding bearing approaches the thickness of the hardened layer, do not simply scrap it at once (the shaft can be polished and reused), but only replace it with a new set of sliding bearings, as the price of the shaft is several times that of the bearing, which can extend the service life of the pump shaft.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071