Why is the melt pump extrusion unable to discharge?

Reasons and specific solutions for the inability to discharge materials during the use of high-temperature melt pump extrusion:

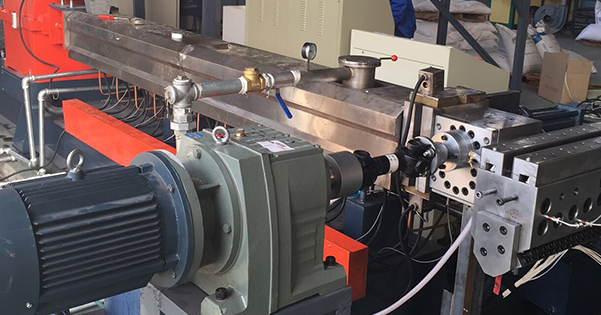

melt pump extrusion

The reason why the hot melt pump cannot discharge:

1. The rotation direction of the high-temperature melt pump in extruder is reversed, resulting in abnormal discharge;

2. The suction or discharge valve is closed, resulting in the inability to discharge;

3. The channel of the high-temperature melt pump is empty or the inlet working pressure is too low;

4. The viscosity of the conveyed melt is too high, and the high-temperature melt pump cannot bite the material.

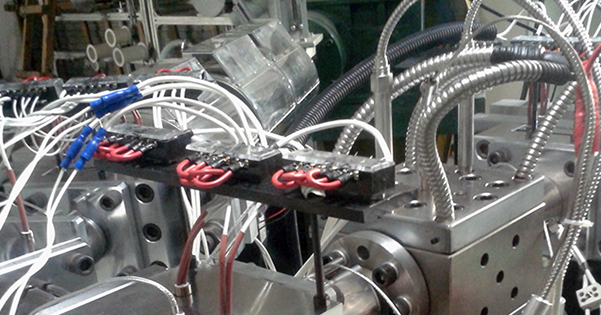

hot melt pump

Solutions provided by Zhengzhou BATTE melt pump manufacturer:

1. Determine the rotation direction of the high-temperature melt pump;

2. Determine if the gate valve is closed;

3. Check the gate valve and pressure gauge;

4. Check the viscosity of the melt.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071