Composition and operation of melt pump control system

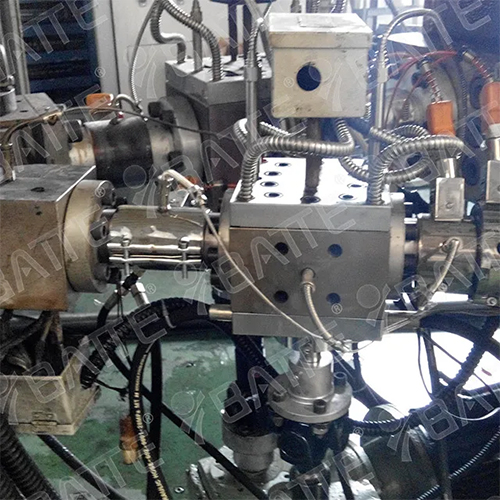

The basic composition of the melt pump control system includes, sensors: temperature sensors (such as PT100 RTD), pressure sensors (transmitters), displacement sensors, etc.; controllers: intelligent instrumentation, PLC, etc.; actuators: electric heating plates, electric heating rods, inverter motors, inverters and so on.

Melt pump control system is an important part to ensure the stable operation of the melt pump, combined with the melt pump can be a full range of pressure, temperature, flow, speed control, to achieve automatic or manual control functions, optimization of the control system can be well eliminated by a variety of factors caused by the pressure fluctuations in the extruder, stabilize the pressure of the discharge port, and maximize the melt pump in the precision of the advantages of extrusion.

Melt pump control method mostly adopts closed-loop control:

1, through the pressure sensor to obtain the outlet pressure, and inverter drive stroke closed loop, automatically adjust the speed to achieve the purpose of pressure stabilization;

2, through the pressure sensor to obtain the inlet pressure, the signal feedback to the upper (such as extruder), to achieve the stability of the inlet pressure to ensure the stability of the melt pump feed;

3, through the temperature sensor to obtain the temperature of the pump body, and heating device stroke closed loop, to achieve automatic temperature control.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071