Small melt gear pump

I. Basic Definition and Functional Positioning

Small Melt Gear Pump belongs to positive displacement conveying equipment, designed for high temperature (≤350℃), high viscosity (1~40,000 Pa-s) polymer melts, which are widely used in extrusion molding scenarios, such as pelletizing, film, and pipe. Its core functions include:

Stable delivery: volumetric metering through gear meshing, flow rate is independent of pressure fluctuations, ensuring dimensional accuracy of extruded products.

Pressurization matching: connected in series between the extruder and the head, it compensates for pressure loss and improves melt uniformity.

Energy saving and consumption reduction: when combined with twin-screw extruder, mixing quality is improved by 25% and energy consumption is reduced by about 25%.

II. Technical characteristics and parameter range

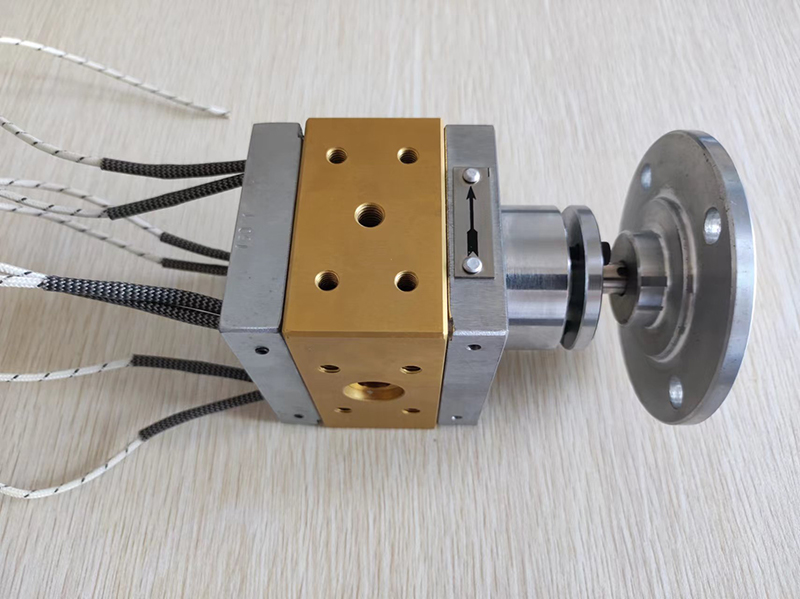

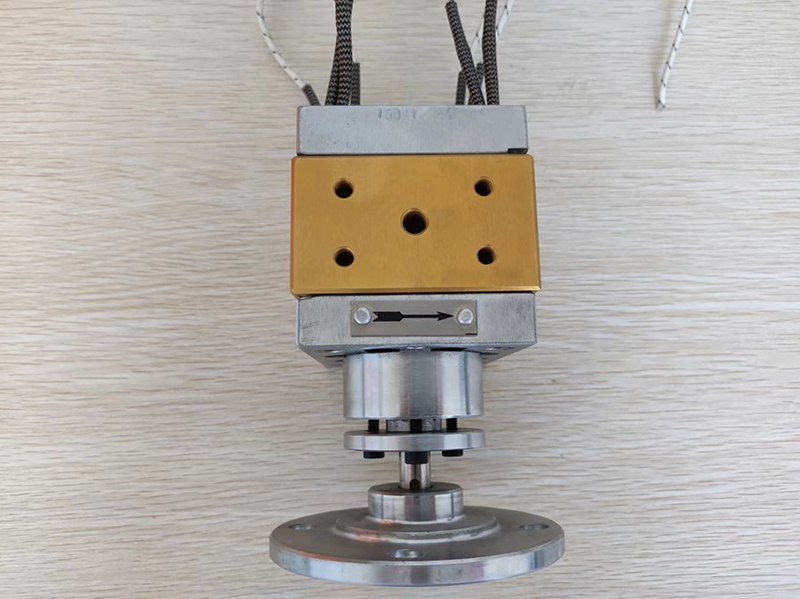

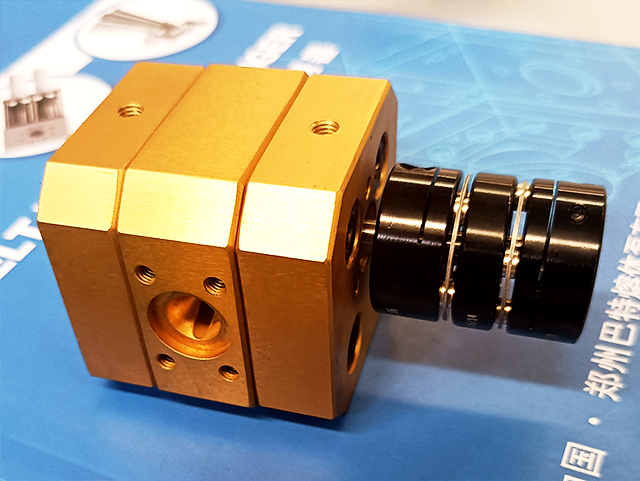

Structure composition

Core components: pump casing, gear shaft, sliding bearings, shaft seal (with filler seal or mechanical screw seal).

Gear type: straight teeth, helical teeth (preferred for high viscosity conditions), herringbone teeth, etc., the tooth profile is mostly involute or circular arc.

Material: high temperature alloy steel, special heat treatment, high hardness but brittle, need to avoid impact.

Key parameters

Flow rate range: 1~100000 cc/r (small pumps usually below 1000 cc/r).

Pressure capability: suction pressure 0~30 MPa, output pressure 0~40 MPa, permissible differential pressure 25 MPa.

Temperature adaptability: ≤350°C, heating methods include thermal medium heating, electric heating, etc.

Viscosity coverage: 1~40,000 Pa-s, supporting transportation from low viscosity resin to high viscosity rubber.

Performance Advantages

High volumetric efficiency: stable flow rate, no outlet pressure fluctuation.

Low shear effect: Avoids melt degradation, suitable for heat-sensitive materials (e.g. PLA, PBAT).

Compact structure: modular design, easy to integrate into the existing production line.

III. Typical application scenarios

Small extrusion line

Laboratory R&D: for testing new material formulations, such as extrusion tests of biodegradable plastics (PLA, PBS).

Small batch production: for manufacturing small-diameter pipes, narrow films or precision fibers.

Multi-pump configuration

Multiple small and medium-sized pumps in parallel to feed a single head to produce large products (e.g., wide sheets, large-diameter pipes), reducing the equipment footprint.

Adaptation to special working conditions

Exhaust optimization: Reduce friction between screw and barrel to solve the problem of exhaust air bubbling.

Co-mingling modification: Tandem connection with twin-screw extruder improves mixing uniformity and is suitable for the production of highly filled composite materials.

Small melt gear pumps with high precision and high stability as the core advantage, suitable for small batch, multi-species polymer processing scenarios. Selection needs to focus on flow, viscosity, temperature parameters matching, installation and commissioning need to strictly follow the procedures, regular maintenance can significantly extend the life of the equipment. Domestic products in the technical parameters have been in line with international standards, but there is still room for improvement in material durability, sealing reliability.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071