What problems does a melt pump solve for rigid polyvinyl chloride PVC?

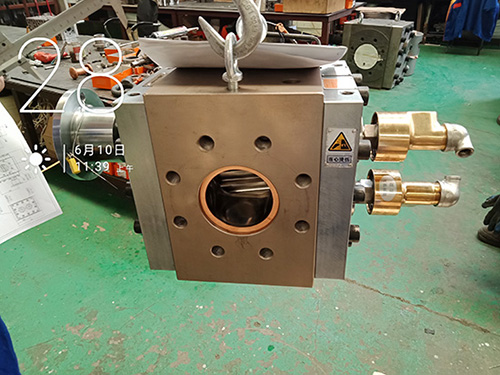

The polyvinyl chloride melt pump is specialized in conveying, pressurizing and metering high viscosity polymers of polyvinyl chloride (PVC). The PVC melt pump is mainly composed of pump casing, driving gear, driven gear, sliding bearing, front and rear plates, packing seal, etc.

The machining of rigid PVC also generally avoids the use of melt pumps because of the heat generated by the axial play of the gears and the lubrication zones in the bearings. While many gear pumps today are capable of expelling the material used for gear and bearing lubrication, maintaining proper low temperatures on bearings and gear journals is still difficult to achieve. The melt pump for rigid PVC developed and designed by Zhengzhou Bart can solve the above problems very well.

Processors of rigid PVC also generally avoid melt pumps extrusion because of the heat generated by the axial play of the gears and lubrication zones in the bearings. While many gear pumps today are capable of expelling the material used for gear and bearing lubrication, maintaining proper low temperatures on bearings and gear journals is still difficult to achieve. The hot melt pump for rigid PVC developed and designed by Zhengzhou Bart can solve the above problems very well.

It is recommended to use a universal coupling to connect the reducer and the melt pump to eliminate the influence of thermal deformation; the melt pump is a positive displacement pump, and the output flow of the pump can be adjusted by adjusting the speed of the pump. Frequency conversion speed regulation is recommended. In this way, the near-linear flow output of the gear pump can be realized. info@battemachinery.com