Influence of Lubrication State on Driving Torque of Meltblown Metering Pump

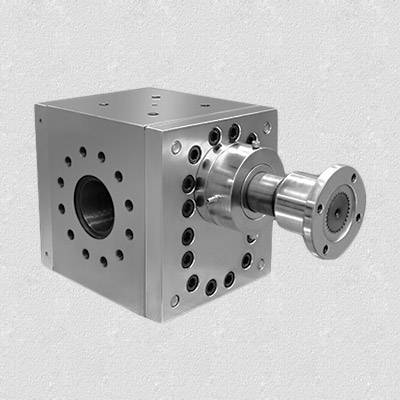

The internal rotating parts of the melt-blown metering pump, such as the driving gear shaft, the driven gear and the shaft, and the meshing gear, are directly lubricated by the melt entering the pump, and the internally rotating coupling is also lubricated by the melt. In the design, there is a gap of about 10μm between the driving gear shaft and the pump casing. The end cover and the packing seal are fixed together by bolts, and the end cover presses the coupling.

When the end cover is pressed loosely, the lubricating gap is within a reasonable range, and there is a leakage of melt from the inside of the pump. Generally, the leakage is controlled at 10-15g/d, so that the coupling is fully lubricated. However, if the leakage is too large, there will be obvious slurry leakage, which will affect the safe operation and on-site maintenance work. Another situation is that the amount of leakage is small or there is no leakage. At this time, the coupling appears dry friction, and the driving torque rises significantly. In severe cases, the coupling will bite and get stuck, resulting in motor overload protection or shearing of the safety pin. In view of the above situation, it is required to regularly check and adjust the lubrication condition of the meltblown metering pump. Zhengzhou Batte provides 65-machine meltblown metering melt pump, 90-machine meltblown hot melt pump, 120-machine meltblown melt pump extrusion, etc. info@battemachinery.com