Melt pump for TPU thermoplastic elastomers

TPU elastomer melt pump is a specialized extrusion system for rubber and elastomer melt gear pump, which is suitable for the extrusion and transportation of rubber and elastomer melts; Generally installed between the outlet of the extruder and the die head, used as a melt metering pump; The pump casing of the TPU elastomer melt pump has a built-in flow channel, which can be used for cooling or heating the heating medium.

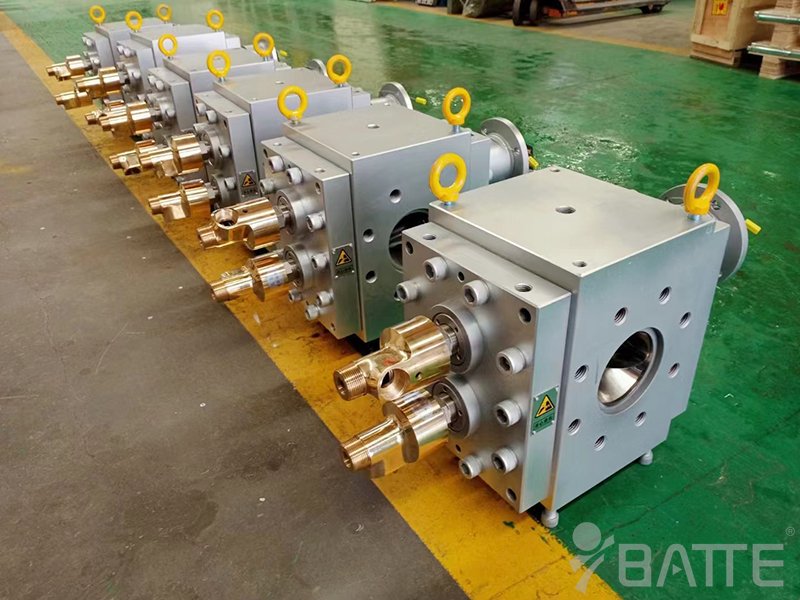

TPU elastomer melt pump

Main characteristics of melt pumps for TPU elastomers

1. Optimized melt flow channel design: eliminates dead corners within the channel, minimizes polymer residue, and improves product quality;

2. Optional built-in flow channel: suitable for fluid cooling to adapt to more precise and fast temperature control systems; It can also be used for heating medium;

3. Improved gear parameter design: more precise displacement design, making the output pressure more stable and suitable for precision extrusion conditions;

4. Very wide range of applicable viscosity: using different sealing methods, it can be applied to working conditions from low viscosity to extremely high viscosity;

5. Multiple installation methods: meet the personalized needs of users;

6. High precision manufacturing and excellent heat treatment: more precise and durable.

elastomer melt gear pump

Technical parameters of melt pumps for TPU elastomers

Transmission medium viscosity: 1-40000Pa • s

Suction pressure: 0-30MPa

Output pressure: 0-40MPa

Allowable pressure difference: ≤ 25MPa

Operating temperature: ≤ 350 ℃

Heating method: electric heating/heating medium flow channel heating

elastomer extrusion melt gear pump

Installation method of melt pump for TPU elastomer

It is recommended to use a universal coupling to connect the reducer and melt pump to eliminate the influence of thermal deformation; The melt gear pump belongs to a positive displacement forced delivery pump, and the pump output flow can be adjusted by adjusting the pump speed. It is recommended to use a frequency conversion speed control method to achieve nearly linear flow output of the gear pump.

TPU elastic melt gear pump

Melt pump selection parameters

The selection needs to provide parameters: 1. Flow rate or output; 2. Material name; 3. Material viscosity; 4. Corrosiveness/toxicity of materials; 5. Inlet and outlet pressure (pressure difference); 6. Operating temperature. The flow rate of the melt pump is related to the working speed, material viscosity, and working pressure. Please consult the manufacturer for specific selection.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071