Melt Pump for Plastic Sheet Extrusion Machines

In plastic sheet extrusion production lines, the melt pump serves as the core equipment for pressure stabilization, flow regulation, and efficiency enhancement. It accommodates extrusion processes for various sheet materials including PE, PP, PVC, PET, and PS. Its primary value lies in resolving pulsation issues in extruder screw conveyance, ensuring uniform sheet thickness and surface quality.

Core Function (Addressing Sheet Extrusion Specifics)

Eliminate melt pulsation to ensure thickness precision

The distinct conveying characteristics of the extruder screw's feeding, compression, and metering sections cause periodic fluctuations in melt flow and pressure, directly leading to sheet thickness deviations. The melt pump employs high-precision gear meshing for forced melt conveyance, controlling pressure fluctuations within ±0.5MPa. This enables stable sheet thickness tolerances of ±0.01mm (meeting high-precision sheet requirements).

Enhanced Extrusion Stability for Superior Surface Quality

Consistent melt flow prevents surface defects like streaks, bubbles, and crystalline spots caused by flow rate fluctuations. This is particularly advantageous for transparent sheets (e.g., PET, PS sheets) and high-end packaging sheet production.

Reduce extruder load and boost production capacity

The melt pump shoulders part of the melt pressurization task, reducing backpressure load on the extruder screw. This increases screw plasticizing efficiency by 10%–20% while minimizing screw wear and extending service life.

Precise output control for varying sheet widths

Adjusting the melt pump speed enables precise regulation of melt flow rate, facilitating rapid switching between different sheet width and thickness specifications without frequent extruder parameter adjustments.

Process Layout and Compatibility Requirements

1. Typical Layout Configuration

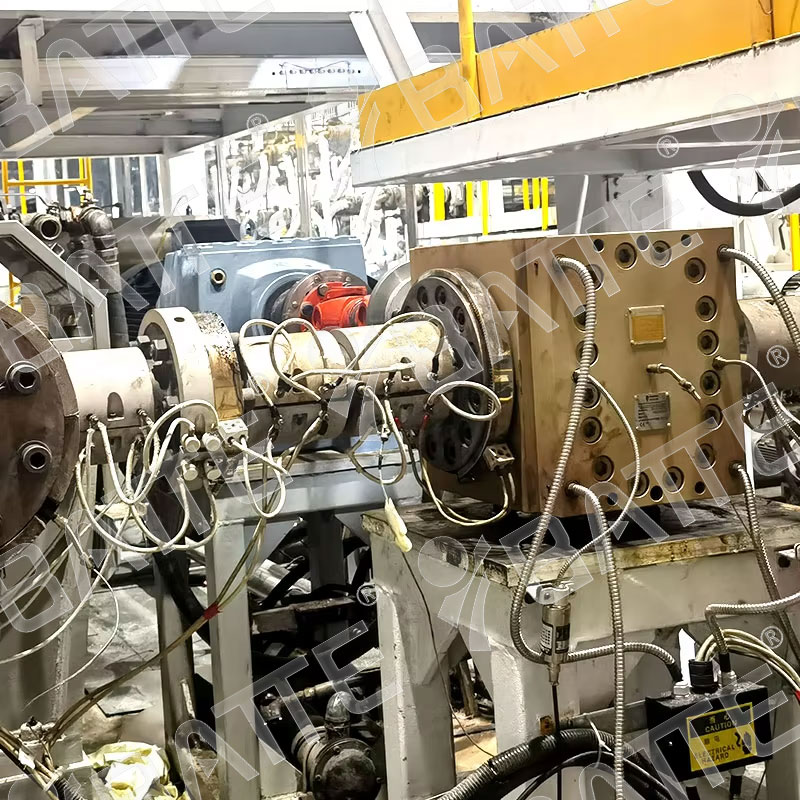

Extruder → Melt Filter (or Screen Changer) → Melt Pump → Die (T-Die) → Calender → Take-up

The melt pump must be positioned after the filter/screen changer and before the die: Filtered melt free of impurities prevents contamination entering the pump body, reducing gear wear. Proximity to the die minimizes melt transport distance and pressure loss.

For heat-sensitive materials (e.g., PVC, PET), install precise temperature control units before and after the melt pump, maintaining temperature deviation within ±1°C to prevent melt degradation.

2. Matching Principles with the Extruder

Flow Rate Matching: The melt pump's rated flow rate should slightly exceed the extruder's maximum output (typically with a 10% margin). For example, a 500 kg/h extruder requires a melt pump rated at 600 kg/h.

Pressure Matching: The maximum operating pressure of the melt pump must be ≥ the pressure required by the die (sheet extrusion dies typically require 8–15MPa) to ensure stable melt filling of the mold cavity.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071