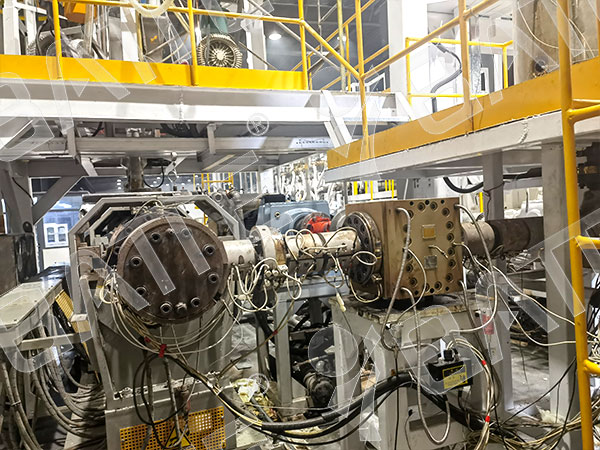

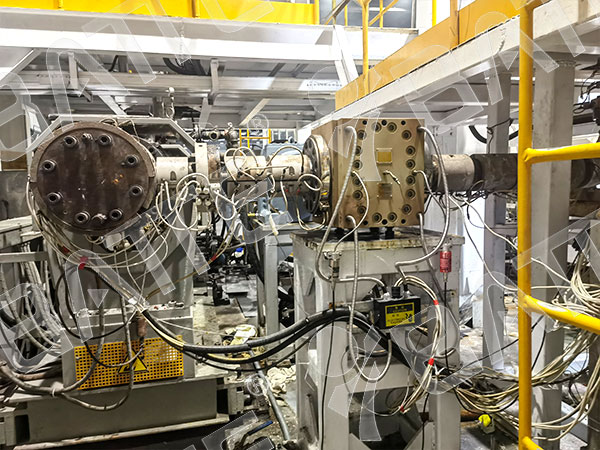

3200CC Melt Pump for BOPP Film Extruder

The 3200CC melt pump serves as the core pressure-stabilizing metering equipment for BOPP film extrusion lines. Mainstream models like the ZB-3200 deliver a displacement of 3200 cm³/rev, compatible with production lines ranging from 2000 to 7000 kg/h. It maintains pressure fluctuations within ±1%, significantly enhancing film thickness uniformity.

Core Parameters and Structure

Displacement: 3200 cm³/rev

Output Range: 2000–7000 kg/h

Center Distance / Tooth Width: 180 mm/180 mm

Weight: Approx. 1200 kg

Operating Temperature: ≤350°C

Operating Pressure: ≤40 MPa

Viscosity Compatibility: ≤40,000 Pa·s

Heating Method: Electric Heating Rod Multi-zone temperature control

Sealing: Double-Ended Helical Seal Optional water cooling ring assistance

Pump Body: High-Temperature Alloy Steel;

Gears: Nitrided Steel / Tool Steel;

Bushings: Tool Steel / Copper-Aluminum Alloy

Custom coatings and materials available based on operating conditions

Core Value of Melt Pumps in BOPP Extrusion

Pressure Stabilization & Metering: Converts extruder's pressure-flow coupling output to decoupled control, achieving instantaneous flow fluctuations ≤±0.5% and pressure fluctuations ≤±1%, significantly reducing film thickness deviation.

Quality Enhancement & Efficiency Boost: Reduces melt pulsation, minimizes defects like streaks and bubbles; shares extruder load, saving ~10–15% energy while extending screw lifespan.

Process Adaptability: Linear flow output flexibly matches varying width and thickness requirements via variable frequency/servo speed control, improving material utilization.

Selection and Application Guidelines

Matching Principle: Pump displacement ≥ 120% of maximum production line capacity, allowing process adjustment margin.

Pre-filtration: Recommended 150-mesh or higher screen changer/filter to prevent impurities damaging gear meshing surfaces.

Temperature Control: Maintain temperature differential <2°C between zones to prevent thermal stress lock-ups; keep inlet/outlet differential ≤5°C to avoid melt degradation.

Sealing & Safety: Prioritize spiral seals + cooling rings to ensure leak-free operation under high temperature/pressure.

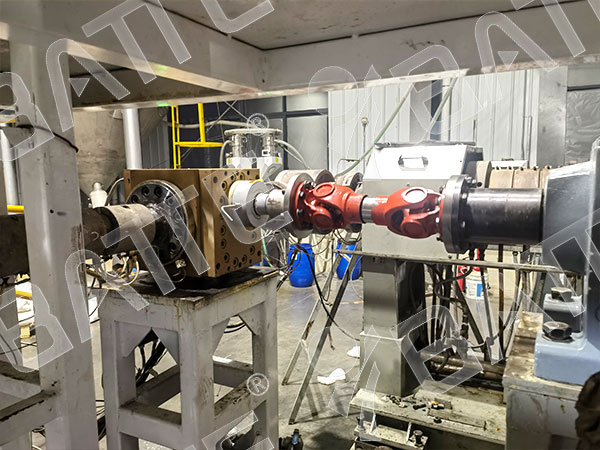

Drive System: Motor + gear reducer + universal coupling; recommend servo speed control for enhanced precision.

We can provide precise speed, pressure settings, and recommended screen changer configurations based on your production line capacity, web width, thickness specifications, and other parameters.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071