Why does the outlet pressure of the melt pump decrease and how to solve it?

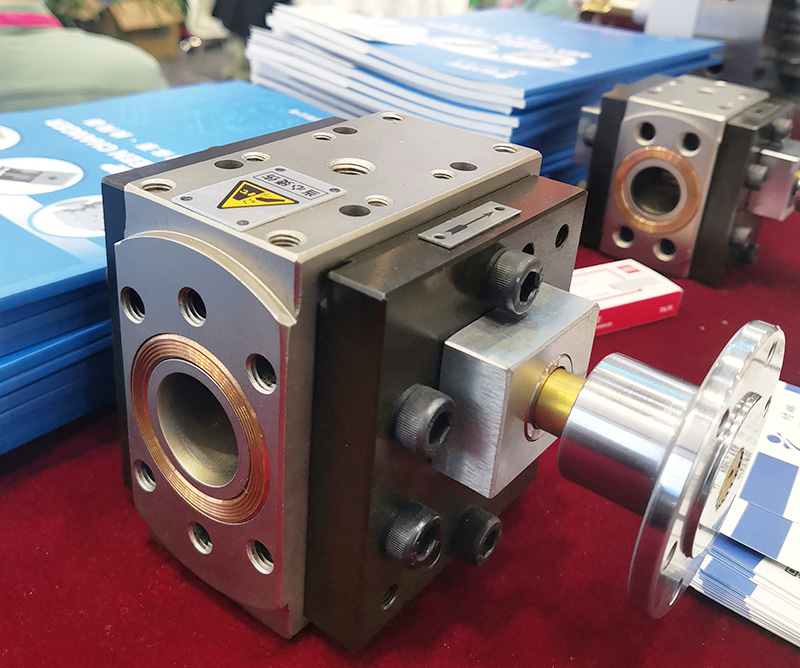

If the outlet pressure of the melt pump is low, the possible cause is wear of the melt pump gear. Because the gears of the melt pump will wear out after a certain period of use, the gap between the gears will increase, causing a greater reflux of the melt, resulting in a much lower outlet pressure of the melt pump compared to normal. The method adopted at this time requires replacing the gear shaft and shaft sleeve of the melt pump. Or in the following situations:

(1) Reason: Insufficient suction volume, solution: Increase the liquid level

(2) Reason: Pump body or inlet leakage, solution: Replace gasket, tighten bolts, repair

(3) Reason: Medium viscosity is high, solution: Reduce medium viscosity

(4) Reason: Excessive axial clearance of the gear, solution: Adjust intermittently

(5) Reason: Insufficient opening of inlet valve, solution: Increase valve opening

The ability of the extruder melt pump to stabilize the outlet pressure is very strong. Generally, ordinary melt pumps can provide ± 1% or better yield uniformity, which can be transformed into excellent product thickness uniformity. A better quality melt pump has a reduction ratio of 50:1 in inlet pressure fluctuation after being pumped, and an outlet pressure fluctuation of less than 0.1 Mpa.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071