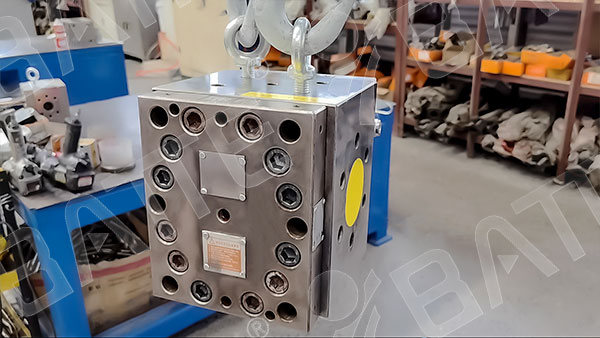

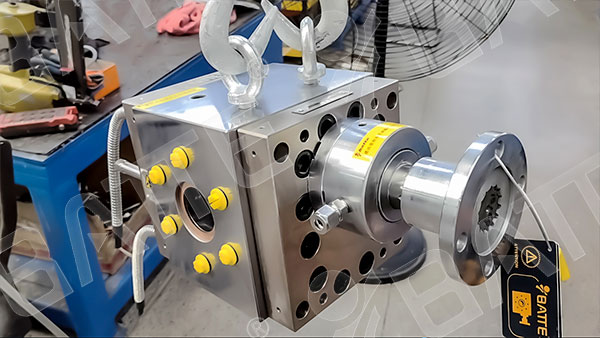

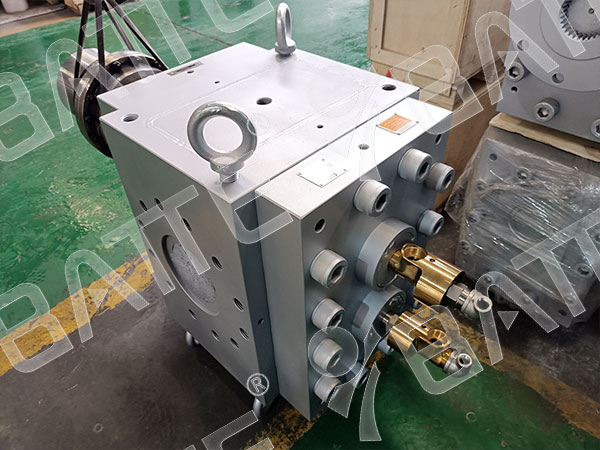

extruder melt gear pump

The extruder melt pump (also known as a metering pump or melt metering pump) is a core precision component in plastic and rubber extrusion production lines. Its primary functions include stabilizing melt pressure, ensuring precise metering and delivery, enhancing the accuracy of extruded products, and resolving quality fluctuations caused by screw pulsation in the extruder.

Core Functions and Value

Pressure and Flow Stabilization: Eliminates pressure pulsations generated by extruder screw rotation, ensuring stable melt flow and pressure to improve product dimensional accuracy (e.g., film thickness uniformity, pipe diameter consistency).

Precise Metering: Utilizes fixed displacement gears within the pump body to accurately control melt delivery volume, enabling constant-speed, fixed-quantity extrusion to meet high-precision production demands (e.g., medical tubing, optical fiber sheathing).

Enhanced Productivity: Reduces extruder back pressure and screw shear heat generation, enabling higher extruder speeds and boosting output by 10%-30%.

Compatibility with High-Viscosity Melts: Conveys high-temperature (≤400°C) and high-viscosity (1000-10^6 cP) polymer melts (e.g., PE, PP, PVC, rubber), accommodating diverse material processing.

Structure and Working Principle

1. Basic Structure

Pump Body: Constructed from high-temperature alloy materials (e.g., nitrided steel, Hastelloy) for wear and corrosion resistance, designed for high-temperature, high-pressure melt environments.

Gear Pair: Consisting of a drive gear and driven gear (core metering components), their meshing creates a fixed-volume chamber with a constant displacement per revolution.

Drive System: Servo motor / variable frequency motor + gear reducer, precisely controlling rotational speed to regulate melt flow rate.

Heating / Insulation System: Electric heating rods + insulation layer, preventing melt cooling and solidification to maintain fluidity.

Sealing System: Mechanical seal / packing seal, preventing melt leakage and ingress of external contaminants.

2. Working Principle

Melt conveyed by the extruder enters the pump inlet. As the gears rotate, the melt is trapped within the gear tooth valleys and pump chambers, then pushed toward the outlet. By controlling gear speed, the melt is delivered to the mold/downstream equipment with precise volume and pressure.

Typical Applications

Plastic Extrusion: Films (BOPP, PE film), pipes (PE water pipes, PVC conduit), profiles (door/window frames), cable jackets, melt-blown nonwoven lines.

Rubber Processing: Rubber seals, tire compound extrusion, silicone product molding. High-Value Products: Medical catheters, optical-grade plastic profiles, lithium battery separator material conveyance.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071