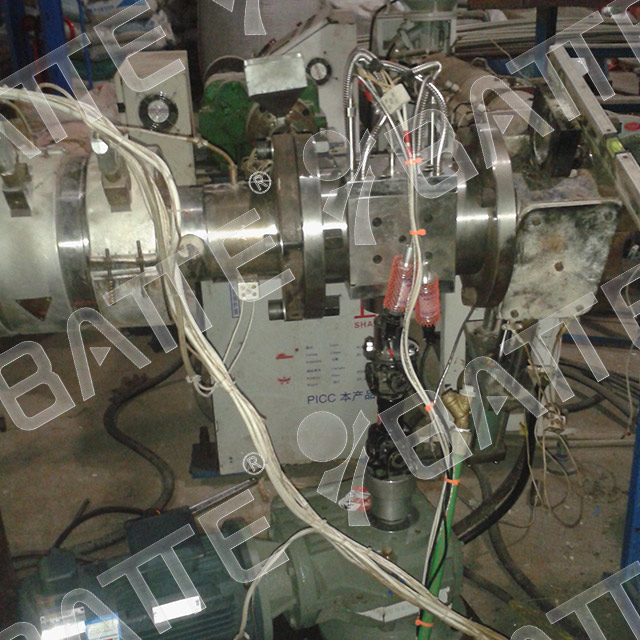

PP-R pipe melt pump

Introduction to PE Pipe Melt Gear Pump

During the extrusion process of high-temperature PP-R pipe melt pumps and PE pipe melt pumps, it is difficult to avoid phenomena such as uneven material feeding, fluctuations in barrel and head temperatures, and pulsations in screw speed. The use of a melt gear pump can eliminate feeding errors in the feeding system, significantly reduce fluctuations in upstream process transmission, quickly enter a stable working state, improve the dimensional accuracy of extruded products, and reduce scrap rates.

The main characteristics of the melt gear pump for pipe extrusion:

1. Can be applied to high temperature (350 ℃), high pressure (35MPa), high viscosity (20000Pas) working conditions;

2. Optimized channel design to avoid dead corners within the channel, reduce material residue, and improve product quality.

3. Improved gear parameter design ensures more stable output pressure and lower pulsation rate, making it suitable for precision extrusion.

4. Adopting high-temperature alloy steel, it has good wear resistance and long service life.

5. Adopting different sealing methods, suitable for a wide range of viscosity.

6. Suitable installation methods can be provided according to different on-site situations of customers, making them more flexible and practical.

Technical parameters of PP-R pipe melt pump:

Transmission medium viscosity: 1~20000Pas (1000~20000000cP)

Inlet pressure: 0-30MPa

Outlet pressure: 0-40MPa

Large pressure difference: 25MPa

Operating temperature: ≤ 350 ℃

Main structure:

Pump body: high-temperature Tool steel chromium nickel alloy steel

Gear: high-temperature Tool steel, nitrided steel, straight or helical teeth

Sliding bearing: high-temperature Tool steel

Shaft seal: spiral mechanical seal, packing seal, spiral packing seal, triple seal

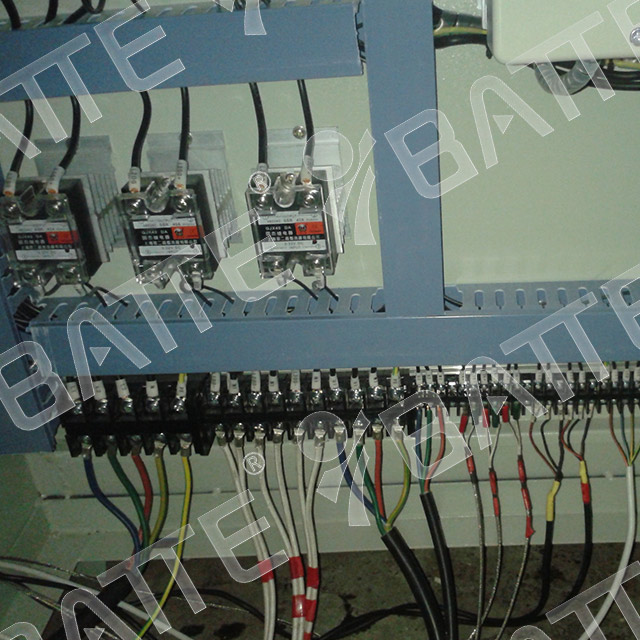

Heating method: electric heating

Specification/flow range: 0.6CC-3200CC

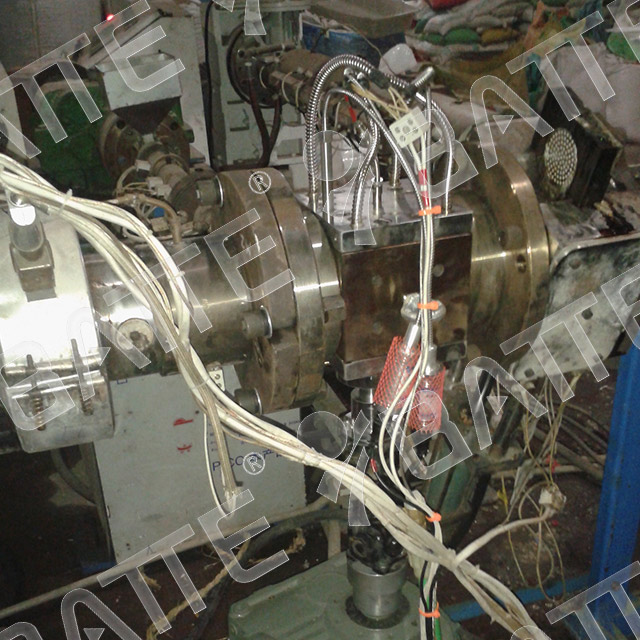

Installation method of pipe melt pump:

The melt pump for pipe extrusion can be installed in various ways, and the input shaft of the melt pump can be arranged horizontally or vertically (both upwards and downwards); The drive system generally includes: motor, reducer, universal coupling, pump connection head, reducer connection head, etc;

The complete equipment includes a melt pump, inlet and outlet connectors, drive systems, control systems, etc. Customers can choose according to specific circumstances.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071