What are the advantages of melt pump for rubber extrusion processing?

1. Low pressure suction, high pressure extrusion

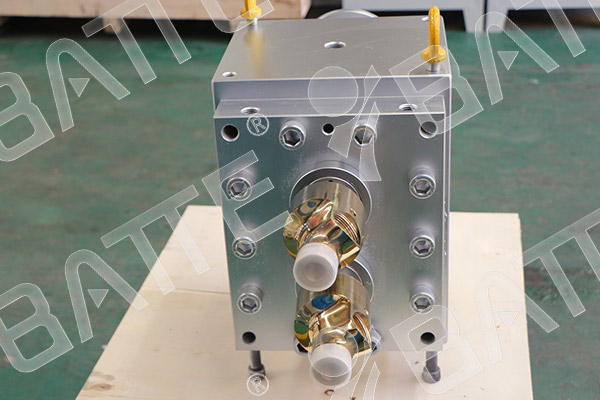

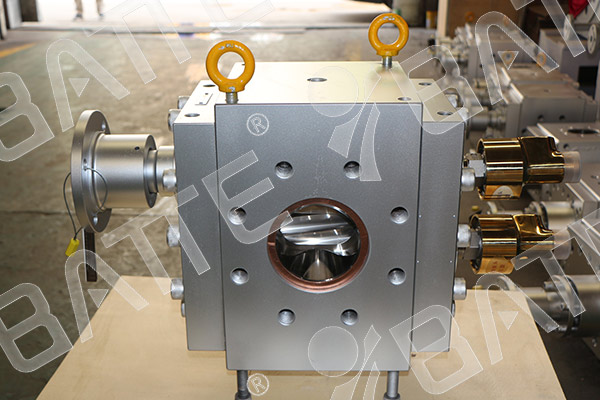

The dynamic meshing line between the rotating tooth surfaces of the gear and the precise fit between the gear and the pump body cavity create a seal on both sides of the inlet and outlet of the pump cavity. The teeth on the feeding side detach from each other, and the volume gradually increases. During this time, the pressure also decreases, and the rubber material is sucked in. The teeth on the discharge side mesh with each other and are embedded into each other's grooves filled with rubber material. The volume of the grooves gradually decreases, and the pressure also increases. The rubber material is mechanically squeezed out.

2. Stable pressure and constant extrusion

The melt gear pump is a positive displacement, positive displacement pump, which is like a piston in a cylinder. When two teeth engage, one tooth enters the groove filled with rubber material, and the rubber material is mechanically squeezed out. As the gears continue to mesh, a continuous discharge is generated on the discharge side of the gear pump. Due to the same volume between the teeth, the discharge is also the same. So as long as the gear speed is constant, the extrusion amount of the rubber material is also relatively constant. Its flow rate depends on the gear speed, and its pressure depends on the resistance at the outlet. This type of stable and constant pressure extrusion is more conducive to the continuous extrusion processing of precision products than an extruder.

3. Process safety

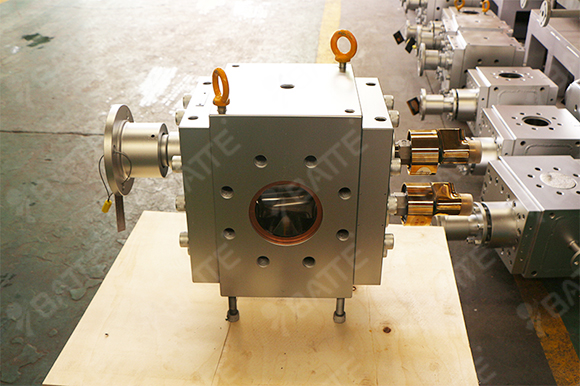

Due to the single and short process experienced by the rubber material in the gear pump, the external force acting on the rubber material can be said to be almost instantaneous when the gear rotates at high speed. Therefore, it undergoes less shear and friction, generates low heat, is not easy to burn, and has a high safety factor. It provides advantages for applications such as extrusion of precision products, filtration of rubber materials, and supply of materials for processes such as rolling. At the same time, the overall processing and assembly accuracy requirements of the rubber melt gear pump are high, so the self-cleaning function of high-quality gear pumps is strong, which can basically avoid dead corners and scorching of the rubber material flow in the pump chamber.

4. Low energy consumption and high efficiency

Due to the fact that the melt gear pump moves a small amount of rubber material through small friction to achieve the effect of extrusion, its energy consumption is much smaller than that of an extruder, while its efficiency is multiplied.

5. Simple lubrication

During the operation of the melt gear pump, the lubrication between the bearings inside the pump body and the various parts on both sides of the gear is achieved solely by the matching accuracy and the self-lubricating adhesive film generated by the adhesive, and a small amount of lubricating adhesive is always discharged from the clearance gap of the sliding bearing. Although its efficiency can reach 93% to 98% in practical production applications, the cumulative total amount of discharged rubber material cannot be ignored for long-term and continuous production. Fortunately, the temperature of the pump body is low (the circulating water temperature of the pump body should be strictly controlled during the production process), and the rubber material undergoes a short time and generates less heat. Therefore, the discharged rubber material is not burnt and can still be returned for reuse.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071