What are the criteria for checking the shaft seal of a melt pump extrusion?

The shaft seal of melt pump extrusion usually adopts packing seal and mechanical seal as well as the combination of the two sealing methods; the following four points are the inspection standards for the shaft seal.

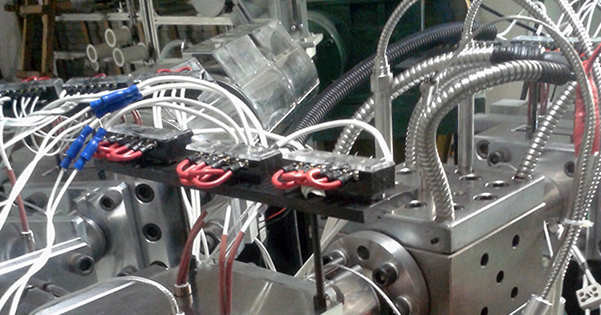

melt pump extrusion

1、The radial clearance between packing gland and shaft is 0.4 ~ 0.5mm, and the circumferential clearance is uniform.

2、Packing size is correct, cut parallel, neat, no loosening, the interface and the shaft centerline at an angle of 30 °.

3, pressure loading filling, each circle packing interface must be staggered, general interface staggered 120 °, packing should not be pressed too tight.

4、Mechanical seal components installed by 0.2MPa test pressure 30 minutes after passing.

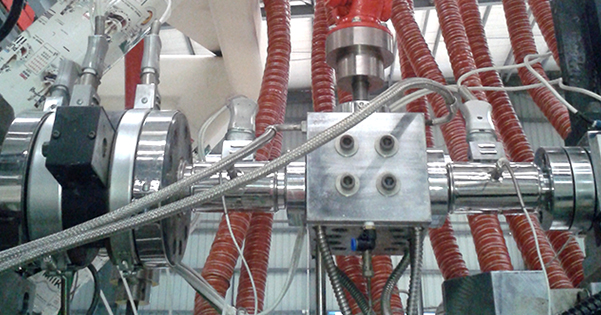

hot melt pump

Melt metering pumps used in resin, chemical fiber, rubber and other polymer industry long cycle, continuous operation conditions, in high temperature, high pressure, high viscosity work, while the material may also be corrosive, particulate impurities, etc., belongs to the high load, poor working conditions, so the hot melt pump materials, processing technology, service life, reliability and so on has very high requirements. The melt pumps provided by Zhengzhou Batte have the advantages of high precision, high strength, high abrasion resistance, high corrosion resistance, high reliability, long cycle continuous operation, etc., which can meet the working conditions of most polymers.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071