Protection of melt pumps by inlet blind during installation

Chemical equipment piping is complex, the installation process often use different types and functions of the blind to play a safe construction and protection of equipment, the common use of blind occasions are:

1, the original drive preparation stage, in the pipeline strength test or tightness test, can not be connected to the equipment (such as turbine, compressor, gasifier, reactor, etc.) at the same time, the need to set up in the equipment and pipeline interface blind;

2, equipment, piping, low-point discharge, if the process media need to be assembled to a common collection system, set up after the blocking valve blind;

3, outside the boundary area connected to the boundary area of the various process materials pipeline, when the equipment is parked, if the pipeline is still in operation, set up a blind plate at the blocking valve.

4、Equipment to be regularly repaired, inspection or mutual switching, the equipment involved needs to be completely blocked when the blocking valve set up at the blind; 5、Pressure charging pipeline, replacement pipeline, the pipeline is still working, in the blocking valve set up at the blind.

5, pressure piping, replacement gas piping (such as nitrogen piping, compressed air piping) process piping and equipment connected to the blocking valve at the time to set up a blind plate.

6, equipment and pipeline exhaust pipe, liquid discharge pipe, sampling pipe in the valve should be set up after the blind or silk plug, no health hazards and non-explosive hazardous materials, except for;

7, equipment for normal production, the need for complete blocking of some auxiliary piping, generally also set up blind.

Blind plate is a reliable isolation device, need to be configured according to the requirements, otherwise it is easy to produce safety accidents and quality accidents.

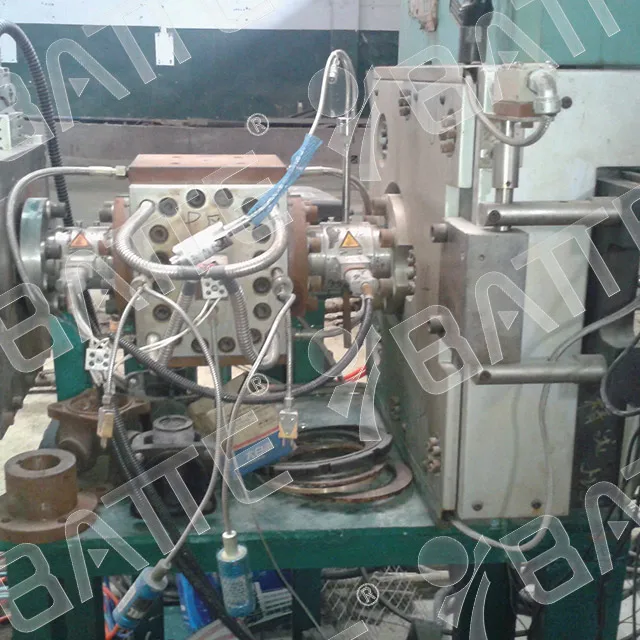

Zhengzhou BATTE as a manufacturer of melt gear pumps, the quality of the product control has strict requirements, the transportation and installation process of protection also has a wealth of experience, the blind has an important role in the initial installation of the melt pump protection.

Due to the complex environment of the construction site, many operators, more uncontrollable factors, in order to protect the discharge melt pump should be configured in the pump body at the entrance end of the blind, because the discharge melt pump is installed in the bottom of the kettle after the entrance to the upward, if not set up the entrance blind, the construction period will occur during the pipeline and kettle of foreign objects (weld slag, screws, tools, etc.) into the pump body, resulting in a greater risk of contamination of foreign objects, resulting in the rotation of melt pumps stagnant or even jammed, causing Difficulty in coiling and different degrees of damage to the melt pump, increase the difficulty of troubleshooting the problem of delayed start node, serious or even damage damage to the melt pump caused by production stoppage, so it is very important to configure the melt pump inlet protection blind plate during the installation stage of the equipment.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071