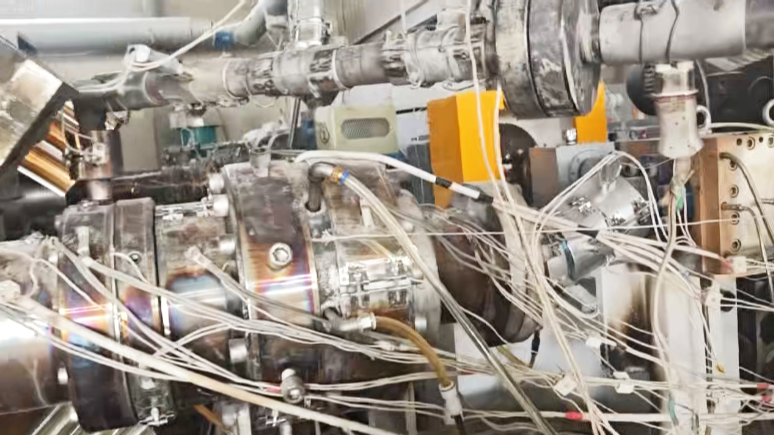

double-axis driven melt pumps

In the production of HDPE pipelines, double-axis driven melt pumps (also known as dual-shaft melt pumps) can be used to improve production efficiency and product quality. Here is a detailed analysis of its application and advantages:

1. Technical characteristics of double-axis driven melt pumps

Dual-shaft structure: The double-axis driven melt pump adopts a dual-shaft design, which can effectively disperse load pressure, avoid single-shaft overload and deflection problems, and improve the system's load-bearing capacity and operational reliability.

High-precision control: This type of pump has high-precision flow and pressure control capabilities, ensuring uniform melt flow and stable pressure during the production process, thereby improving product quality.

High-temperature and high-pressure resistance: Double-axis driven melt pumps are usually made of high-temperature-resistant and wear-resistant materials, such as high-temperature tool steel and nitrided steel, enabling them to operate stably under high-temperature and high-pressure conditions.

2. Advantages in HDPE pipeline production

Stable extrusion: In the production process of HDPE pipelines, the double-axis driven melt pump can eliminate feeding errors in the feeding system, significantly reduce fluctuations transmitted from upstream processes, and quickly enter a stable working state, thereby improving the dimensional accuracy of extruded products and reducing the defect rate.

Increased production and reduced energy consumption: By installing a polymer melt pump on the extruder, the decompression function of the extruder is transferred to the gear pump for completion, allowing the extruder to operate under low-pressure and low-temperature conditions. This reduces leakage flow, increases production, and enables low-temperature extrusion, extending machine life.

Linear extrusion characteristics: The double-axis driven melt pump has minimal leakage flow, and its conveying capacity is basically linearly related to the rotational speed. Therefore, by changing the rotational speed of the gear pump, its flow rate can be accurately determined, facilitating coordination between upstream and downstream equipment and realizing the entire extrusion process through online monitoring and feedback control.

3. Application cases

HDPE double-wall corrugated pipe production line: In the production process of HDPE double-wall corrugated pipes, the double-axis driven melt pump can be used to accurately control the flow and pressure of the melt, ensuring the uniform wall thickness and smooth inner and outer surfaces of the pipes.

Large-diameter HDPE pipeline production: When producing large-diameter HDPE pipelines, multiple small and medium-sized extruders can be used to simultaneously supply material to one double-axis driven melt pump. The molten material is then pressurized and metered by the melt pump and supplied to the die head for extrusion of large-sized products (such as large-diameter pipes, wide plates, and films). This configuration results in a compact production line structure, small footprint, and more precise cross-sectional dimensions of the extruded products, which are easy to control.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071