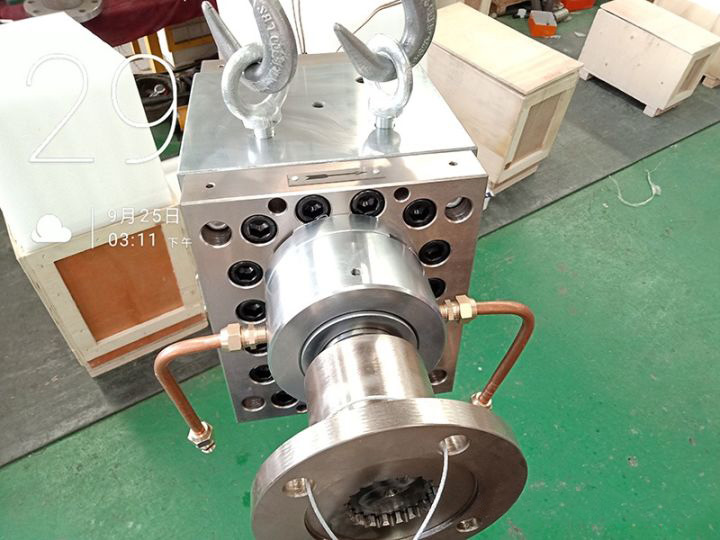

Single screw extruder melt pump gear pump

The single screw extruder melt gear pump is one of the important equipment in modern chemical production, widely used in the production process of plastics, rubber, chemical fiber and other industries. This article will provide a detailed introduction to the working principle, structural characteristics, application areas, and maintenance knowledge of the melt gear pump in a single screw extruder, in order to help readers better understand and apply the equipment.

1、 Working principle

The working principle of the melt gear pump in a single screw extruder mainly utilizes the rotational action of the screw to feed the material into the pump body from the inlet. Through the pushing and shearing action of the screw, the material forms a certain pressure inside the pump body and is transported to the next production process through the outlet pipeline. In this process, the melt gear pump plays a crucial role, by rotating and meshing the gears, the material is subjected to strong shear and friction in the gear clearance, thereby achieving the purpose of pumping and melting.

2、 Structural characteristics

The melt gear pump of a single screw extruder mainly consists of a pump body, screws, gears, bearings, seals, etc. Among them, the pump body is the core component of the pump, usually made of high-performance materials that are wear-resistant and corrosion-resistant to ensure the long-term stable operation of the pump. The screw is the main working component of the pump, and its surface has undergone special treatment, which has good wear resistance and corrosion resistance. Gears are one of the key components of pumps, and their meshing accuracy and wear resistance directly affect the working efficiency and lifespan of pumps. In addition, bearings and seals are also important components of the pump, and their quality and performance directly affect the stability and reliability of the pump.

3、 Application field

The single screw extruder melt gear pump is widely used in the production process of industries such as plastics, rubber, and chemical fibers. In the plastic industry, this equipment is mainly used for the melting and transportation of plastic particles, as well as the production process of plastic pipes, sheets, films and other products. In the rubber industry, this equipment is mainly used for the melting and transportation of rubber materials, as well as the production process of rubber products. In addition, the device can also be applied in the production process of industries such as chemical fiber, paint, and coatings.

4、 Maintenance and upkeep

In order to ensure the long-term stable operation of the melt gear pump in the single screw extruder, proper maintenance and upkeep are crucial. Firstly, the various components of the pump, such as the pump body, screws, gears, etc., should be regularly inspected to ensure that they are free from wear, cracks, and other issues. Secondly, vulnerable parts such as bearings and seals should be replaced regularly to avoid performance degradation or leakage caused by wear and tear of the pump. In addition, the interior and exterior of the pump should be regularly cleaned to maintain cleanliness and hygiene. During maintenance, attention should be paid to using appropriate tools and materials to avoid unnecessary damage to the pump.

In summary, the plastic sheet pipe tube profile extrusion line melt gear pump of a single screw extruder is one of the important equipment in modern chemical production. Knowledge of its working principle, structural characteristics, application fields, and maintenance is of great significance for the normal operation of the equipment and the improvement of production efficiency. I hope that the introduction in this article can help readers better understand and apply the device, bringing more convenience and benefits to actual production.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071