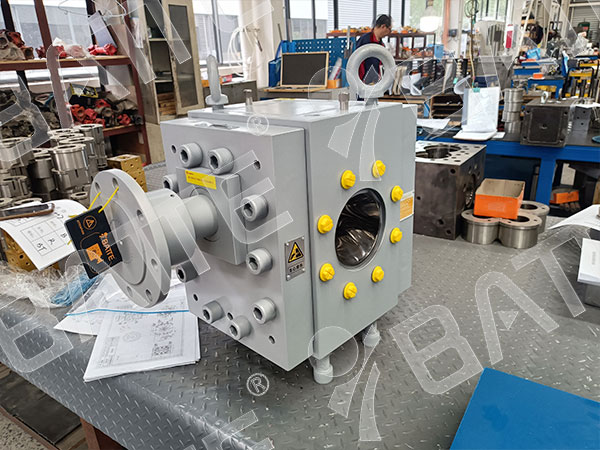

Main Structure and Working Principle of Extruder Melt Pumps

Extruder melt pumps are positive displacement conveyance equipment designed for the transportation, pressurization, and metering of high-temperature, high-viscosity polymer melts. They are widely used in the extrusion molding of plastics, resins, rubber, and other materials. Their core function is to achieve stable melt output through gear meshing, significantly enhancing production efficiency and product quality.

Main Structure and Working Principle

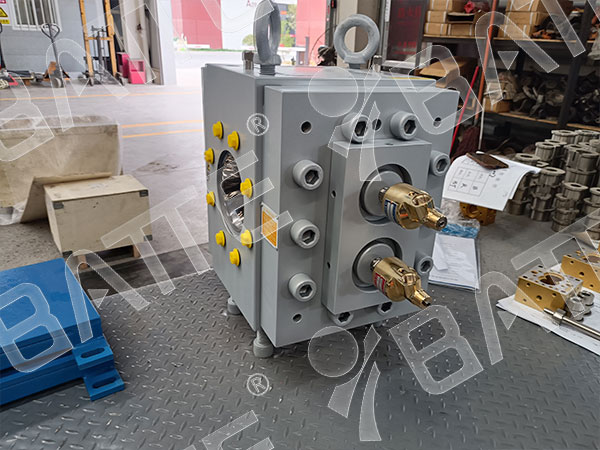

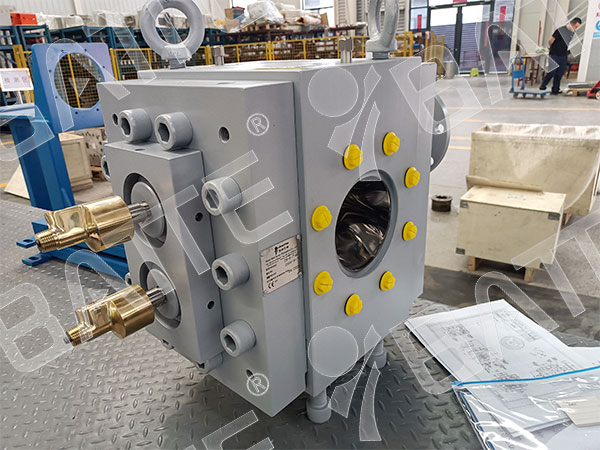

Core Components:Includes the pump housing, drive gear, driven gear, bearings, and sealing assembly. As the gears rotate, the melt is drawn into the gear cavities from the feed zone, compressed through the conveying zone, and discharged into the discharge zone, forming a continuous and stable output.

Operational Characteristics:Flow rate exhibits a strict proportional relationship with rotational speed. Outlet pressure can reach up to 50 MPa, with a wide operating temperature range (maximum 510°C).

Functional Advantages

Pressure Stabilization & Efficiency Enhancement: Eliminates pressure fluctuations in extruder output, reducing energy consumption by over 25%.

Precision Control: Enables accurate flow regulation via variable frequency speed control, minimizing product dimensional tolerances.

Multi-Application Compatibility: Compatible with single/twin-screw extruders, suitable for pelletizing, film, pipe, and other processes.

Typical Applications

Sheet Extrusion: Stabilizes melt pressure to reduce production defects in materials like PET.

Blend Modification: Enables direct extrusion of modified products, simplifying process flows.

Large-Scale Product Manufacturing: Supports parallel feeding from multiple extruders for precision forming of wide sheets or large-diameter pipes.

Melt pump sealing methods (e.g., screw seals or packing seals) and heating solutions (electric heating/thermal fluid heating) must be selected based on material properties.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071