The role of plastic pipe extruder melt pumps

The role of plastic pipe extruder melt pump is mainly reflected in the following five aspects:

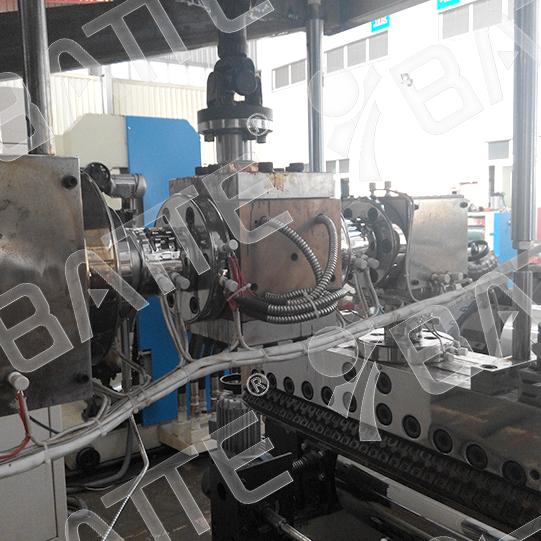

First: the melt pump is the key auxiliary equipment of the extrusion system, the main role is to stabilize the melt pressure and flow.

Second: Through high-precision gear meshing, the melt conveyed by the extruder is forced to stabilize the pressure and then quantitatively output, eliminating the flow fluctuations caused by screw pulsation, and improving the uniformity of pipe wall thickness.

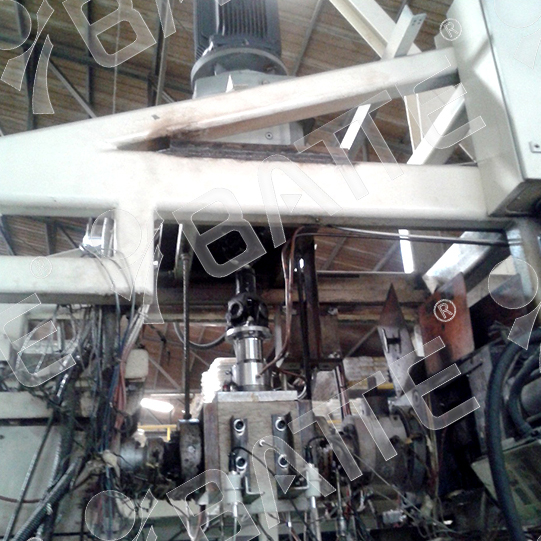

Third. The melt pump can reduce the extruder screw being pressed, reduce shear heat and energy consumption, protect the screw and barrel, and prolong the life of the equipment.

Fourth. For high-viscosity heat-sensitive materials, it can improve the quality of melt plasticization and avoid excessive degradation.

Fifth. Improve the stability of extrusion volume, easy to adjust the rotational speed to accurately control the output, suitable for different specifications of pipe production, especially indispensable in the manufacture of precision pipe, is to protect the accuracy of the product and production efficiency of the core components.

It transfers the depressurization function of the extruder to the melt pump, so that the extruder operates under low pressure and low temperature, and at the same time establishes stable head pressure. Zhengzhou Batte ZB-B series outlet pressure can reach 40MPa, adapting to the conveying needs of high viscosity materials (such as PE, PP, PVC).

When selecting a model, it is necessary to combine the material characteristics, production demand and budget, and give priority to the model with high-precision gears, multiple seals and PLC control functions to maximize the return on investment.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071