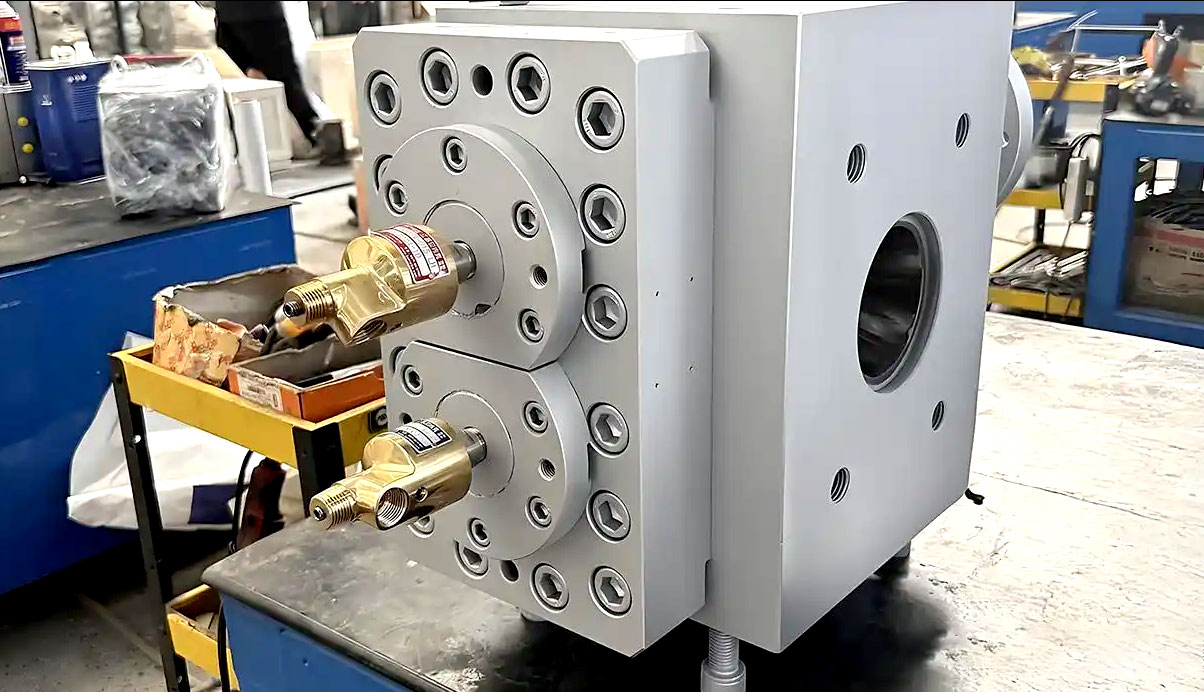

Rubber Melt Gear Pump

The rubber elastomer melt gear pump is a metering and conveying device specifically designed for rubber and elastomer extrusion. Installed between the extruder outlet and the die head, it precisely handles melt metering and conveying functions. Its compatibility spans natural rubber, synthetic elastomers, and biodegradable polymers, serving diverse extrusion applications including sheet, plate, pipe, film, and synthetic fiber filament production. It also supports precision processes like masterbatch extrusion pelletizing and rubber preforming, accommodating various polymer material manufacturing requirements.

Features of Rubber Extrusion Melt Gear Pumps

High Delivery Precision: Utilizing volumetric gear-driven principles, it exhibits minimal pressure and flow pulsation decay, ensuring linear and stable flow output. This enables direct integration with high-end precision extrusion systems, guaranteeing uniform product dimensions and performance.

Extreme Condition Adaptability: Possesses exceptional tolerance for demanding conditions, reliably handling high temperatures up to 350°C, pressures up to 40MPa, and high-viscosity melt conveyance up to 40,000Pass. Customizable structural designs and material configurations are available to match diverse material properties and process parameters.

Reliable Structural Performance: The pump body employs precision machining techniques, with internal flow channels supporting dual temperature control modes—cooling or thermal fluid heating—to accommodate varying melt temperature requirements. Its high structural integrity and low wear rate deliver significantly extended service life compared to conventional equipment.

Features a specialized self-lubricating and sealing structure tailored for the unique properties of rubber and biodegradable materials. An optimized involute tooth profile design further reduces delivery pulsation, enhancing operational stability. The dead-zone-free flow channel design eliminates material stagnation and degradation at the source. Multiple gradient wear-resistant configurations are available to meet the demanding conveying requirements of highly filled materials (e.g., glass fiber-reinforced, mineral-filled), ensuring both adaptability and operational reliability.

Leveraging over a decade of polymer extrusion expertise and experience from thousands of installed systems, Zhengzhou Battte delivers integrated solutions for core equipment including melt gear pumps, dynamic mixers, and screen changers. Addressing industry-specific production challenges, we provide end-to-end services—from process analysis and equipment selection to customized manufacturing—precisely matching high-end extrusion processing requirements.