Polymer Melt Gear Pump

I. Extensive Material Compatibility

Melt gear pumps offer exceptional versatility, efficiently handling the vast majority of polymer materials. Whether processing general-purpose plastics like PE, PP, and PVC; engineering plastics such as PC and PET; or thermoplastic elastomers and various rubbers, they deliver stable conveying performance to meet diverse industrial production demands.

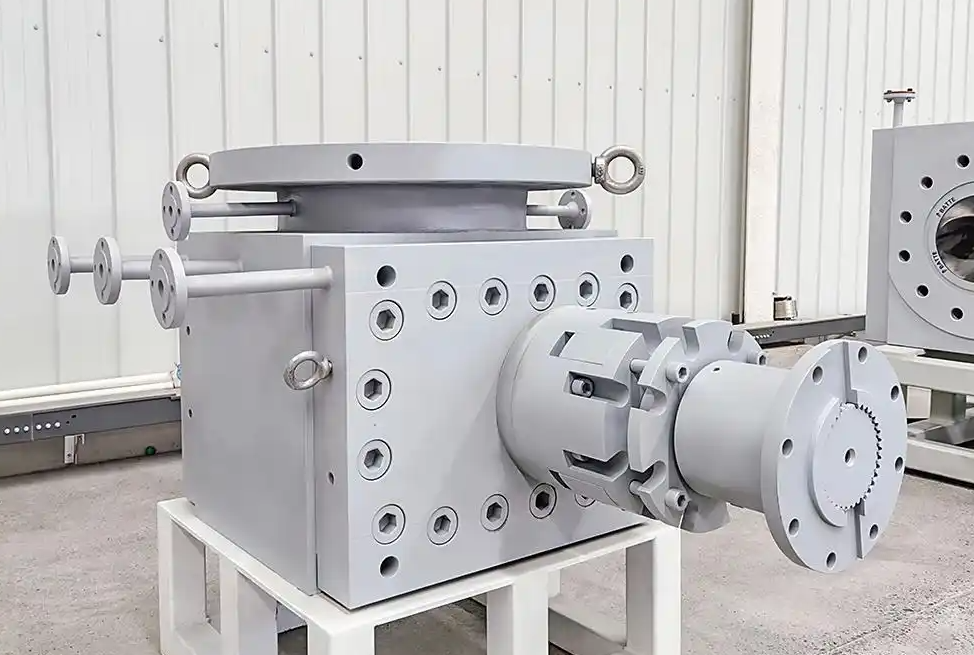

II. Precision Internal Construction

A complete melt gear pump system comprises a drive motor, reducer, connecting assembly, and the core component—the pump head. As the equipment's “heart,” the pump head features exceptionally precise construction. It incorporates an internal pump housing, front and rear end caps, a pair of precision-meshed gear shafts, paired with specialized sliding bearings and high-efficiency shaft seals. This design provides core assurance for stable operation under demanding conditions.

III. Demanding Operating Conditions and Material Selection

Melt gear pumps operate continuously under high-temperature and high-pressure environments, typically enduring temperatures below 350°C and pressures up to 30MPa—extremely challenging conditions. Consequently, pump materials must exhibit high-temperature resistance, wear resistance, and corrosion resistance, while also possessing high strength and long-term dimensional stability to ensure equipment longevity and metering accuracy.

IV. Core Functions and Distinct Advantages

Melt gear pumps primarily fulfill three core tasks: conveying, pressurizing, and precise metering. They offer advantages including compact structure, reliable operation, low energy consumption, and high volumetric efficiency, effectively enhancing production line performance. Additionally, they minimize shear forces on materials, maximizing preservation of the polymer's original properties.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071