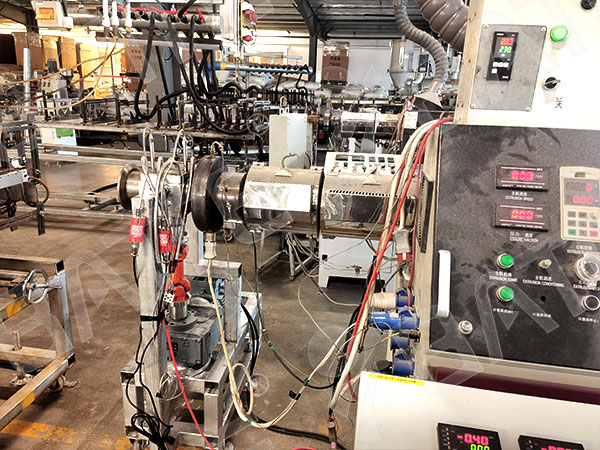

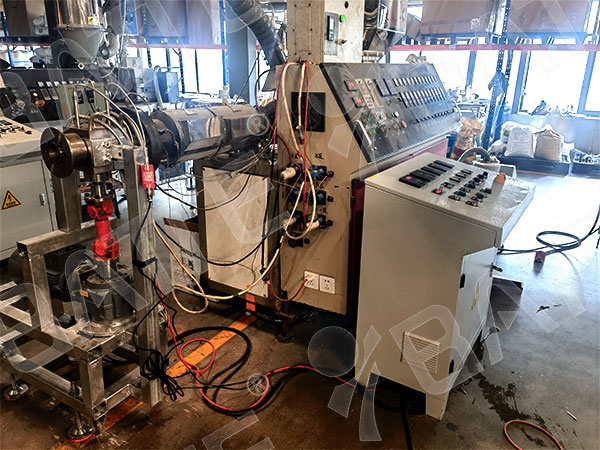

PC Lampshade Profile Extruder Melt Pump

The PC lampshade profile extruder melt pump is a critical piece of equipment in PC lampshade production. It primarily serves to precisely control the delivery pressure and flow rate of PC melt, ensuring product quality and production efficiency. Below is a detailed introduction:

Working Principle

PC lampshade profile extruder melt pumps are typically gear pumps that operate through the meshing of precision gears. As the gears rotate, PC melt enters the pump inlet and is captured within the gear tooth spaces. The rotating gears force the melt toward the outlet. By adjusting the gear rotation speed, the melt output flow rate can be precisely controlled.

Primary Functions

Pressure and Flow Stabilization: Eliminates pressure and flow fluctuations in PC melt caused by variations in material melting state or screw speed during extruder screw conveyance. This ensures dimensional accuracy of lampshades and prevents defects like uneven wall thickness.

Secondary Plasticization: The meshing action of internal gears subjects PC melt to secondary shearing and mixing. This further melts partially unmelted particles, expels micro-bubbles, uniformly disperses additives, enhances melt quality, and improves PC lampshade properties like transparency and gloss.

Load Reduction: Assumes primary melt conveying pressure, reducing extruder screw backpressure. This minimizes wear on the extruder motor, screw, and barrel, extending equipment lifespan while lowering energy consumption and minimizing downtime due to failures.

Process Adaptability: Precisely matches extrusion volume for different PC lampshade specifications by adjusting rotational speed, enabling rapid changeovers and providing stable melt supply for subsequent processes like molding and cooling systems.

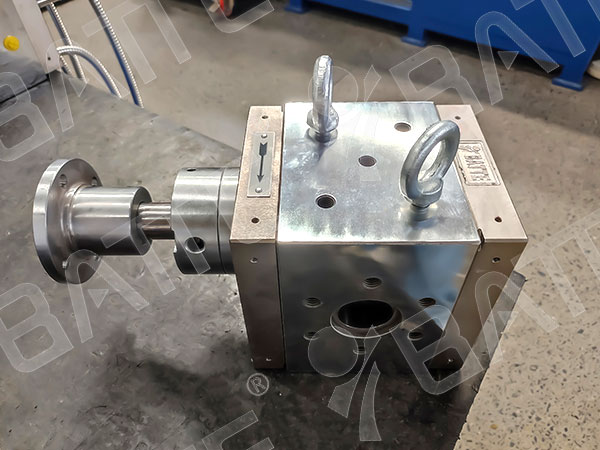

Structural Features

Material: Typically nitrided steel, tool steel, or high-nickel alloy steel, offering excellent high-temperature resistance and corrosion resistance for stable operation in PC lampshade production environments.

Sealing Method: Primarily employs screw seals and packing seals, with alternative mechanical seal configurations available upon customer request to prevent melt leakage.

Heating Method: Primarily electric heating, though thermal fluid jacket heating is also available. This maintains the pump body at an optimal temperature to ensure PC melt fluidity.

Flow Path Design: Optimized flow path design eliminates dead zones within the channels, minimizes material residue, and enhances product quality.

Key Technical Parameters

Flow Rate Range: Typically 0.05–30,000 cc/r. Suitable displacement can be selected based on production requirements.

Operating Temperature: Generally ≤400°C, meeting the processing temperature requirements for PC materials.

Discharge Pressure: Generally ≤40MPa, varying by melt pump model.

Viscosity Range: Capable of conveying PC melt with viscosity ≤40,000Pa・s.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071