Melt pumps are used in transparent nylon pelletizing production lines

Melt pumps play a central role in transparent nylon pelletizing production lines by stabilizing melt pressure and flow rate, enhancing pelletizing precision, improving plasticization efficiency, and reducing equipment load. They are critical equipment for ensuring production continuity and product quality. Below is an analysis of their specific functions and advantages:

I. Core Function: Stabilizing Melt Delivery to Improve Granulation Precision

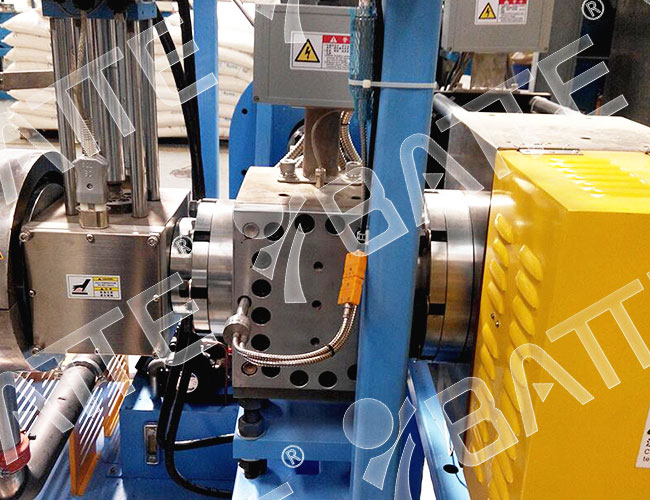

Pressure and Flow Stability

Employing the mechanical pressure amplification principle of gear meshing, the melt pump precisely controls nylon melt pressure and flow rate. This eliminates pulsation fluctuations caused by factors such as extruder screw speed variations and temperature changes. Its outlet pressure fluctuations can be controlled within ±1%, ensuring the melt enters the pelletizing equipment in a stable state. This improves pellet size uniformity and reduces scrap rates. For example, in transparent nylon pelletizing, dimensional tolerances can be minimized, resulting in more consistent pellet appearance that meets high-end application requirements.

Metering and Linear Conveyance

The delivery capacity of melt pumps exhibits a near-linear relationship with rotational speed, enabling precise control of melt output flow by adjusting speed. This characteristic facilitates seamless coordination with upstream/downstream equipment (e.g., extruders, screen changers, die heads) for automated process control and optimization. For instance, in filament drawing or sheet extrusion, melt pumps ensure uniform melt flow, preventing wall thickness inconsistencies or dimensional deviations.

II. Process Optimization: Enhanced Plasticization, Reduced Equipment Load

Improved Plasticization Uniformity

By stabilizing pressure and flow, melt pumps reduce melt residence time within the barrel, stabilize the plasticization process, and lower melt temperatures. This enhances the uniformity of nylon melt plasticization, minimizes unmelted particles or gel particles, thereby ensuring the purity and optical properties of transparent nylon.

Reduced Extruder Load

By assuming the extruder's pressure-reduction function, the melt pump reduces screw pressure requirements. This enables high-speed, efficient extrusion while decreasing axial forces and thrust bearing loads on the gearbox, extending equipment lifespan. For instance, combining a co-rotating twin-screw pelletizing extruder with a melt pump significantly improves mixing quality and output, reducing energy consumption per kilogram of processed material by approximately 25%.

III. Quality Assurance: Filtering Impurities to Maintain Continuous Production Line Operation

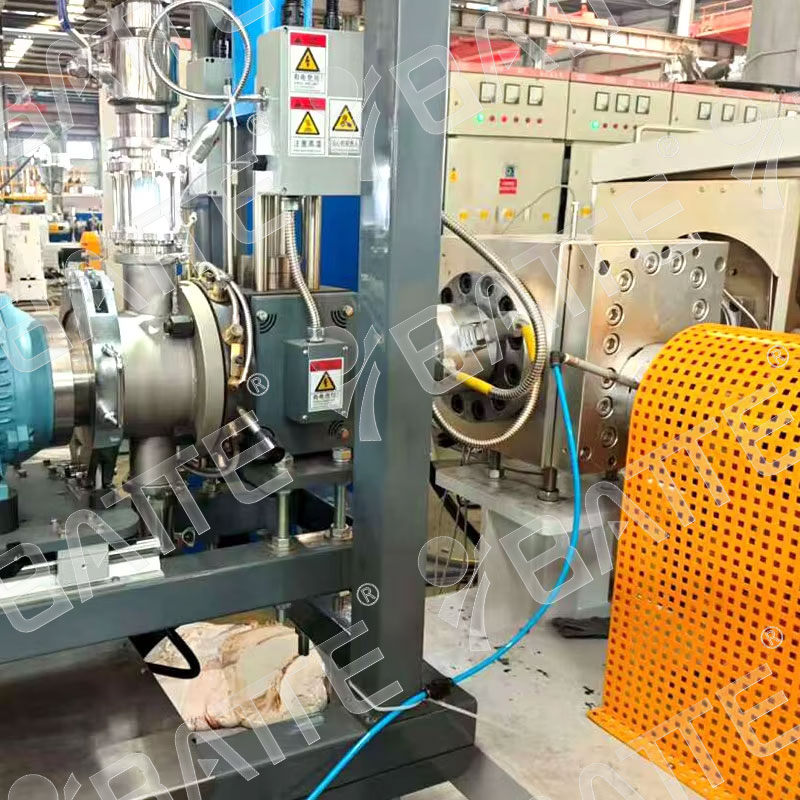

Cooperative Filtration with Screen Changers

In transparent nylon pelletizing, melt pumps are often used in conjunction with screen changers (such as dual-column screen changers). Screen changers filter impurities and gel particles from the melt, preventing die blockages or compromising pellet appearance, while melt pumps ensure uniform delivery of the filtered melt through stable pressure maintenance. This combination enables non-stop screen changes, maintaining continuous production line operation and enhancing efficiency.

Adaptation for High-Viscosity Materials

Manufactured from high-strength alloy steel, the melt pump features gear types including spur and helical gears, with helical gears suited for high-viscosity, high-pressure conditions. Its compact structure and reliable operation ensure stable, long-term performance under high-temperature, high-pressure environments, meeting the conveying demands of high-viscosity materials like transparent nylon.

IV. Application Scenarios and Advantages Summary

Application Scenarios: High-temperature, high-viscosity polymer processing fields including transparent nylon pelletizing, film extrusion, pipe production, and cable filling.

Advantages Summary:

Quality Enhancement: Uniform pellet size and low scrap rate meet the optical performance requirements of premium transparent nylon.

Efficiency Optimization: Increases extrusion output, reduces energy consumption per unit, and extends equipment lifespan.

Process Stability: Adaptable to high-viscosity materials, minimizes melt fluctuations, and ensures continuous production.

Energy Savings & Reduced Consumption: Lowers extruder load and melt temperature, thereby decreasing energy usage and equipment wear.

V. Selection and Installation Recommendations

Selection Criteria: Choose gear type (e.g., helical gears) and material (e.g., high-temperature alloy steel) based on nylon melt viscosity, temperature, and pressure requirements, matching the extruder's flow range.

Installation Notes: Ensure clockwise rotation of the pump shaft; install a fixed base to prevent vibration; configure sensors to monitor pressure and temperature for full online control; start at low speed and gradually adjust to normal operating speed.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071