Features of the Automatic Plastic Granulating Production Line and Function of the Adding Melt Pump

Features of automatic plastic granulation production line:

1. The main and auxiliary machines are used for supporting production, the heating temperature is stable, the molecular structure of materials is effectively improved, the permeability is enhanced, and the particle quality is significantly improved.

2. The plastic granulating unit is mainly composed of the main machine, pulverizer, automatic traction and pelletizer, and the main machine adopts an automatic screen changing device.

3. The screw barrels of the main and auxiliary engines are made of carbon structural steel.

4. The plastic granulator adopts single screw barrel, with fast feeding speed and high output.

5. After classification, crushing and cleaning, all recycled materials can be produced without drying or drying in the sun. They can be used both dry and wet.

6. The split full-automatic power distribution system is adopted to ensure the safe and normal operation of the motor.

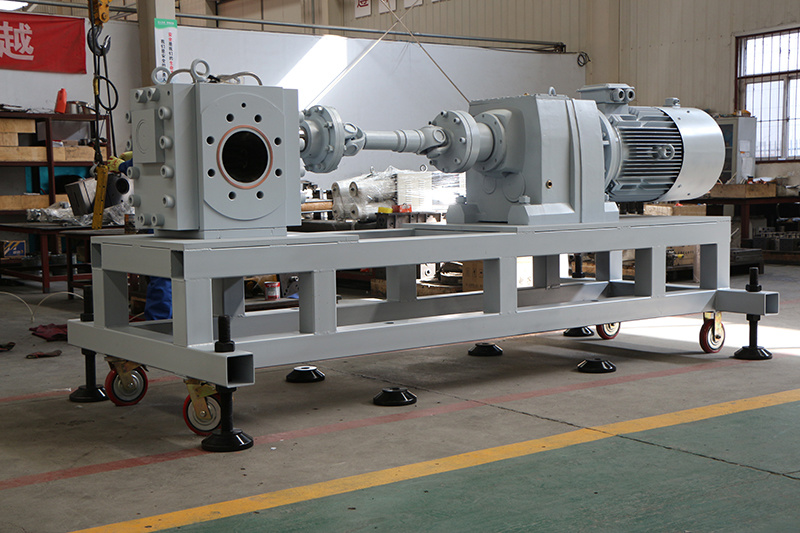

Function of pelletizing melt pump of auxiliary plastic machine for automatic plastic granulation production line

The main function of the melt pump extrusion is to stably feed the high-temperature plastic melt from the extruder into the extruder head after pressurization and stabilization. Its ability to stabilize the melt pressure and flow rate is superior to all types of extruders. When it is used in series with a single screw or co rotating twin screw extruder, the benefit of the whole production line is significantly increased.

The cost of adding hot melt pump system in the extrusion production line is offset by the benefits obtained from the above benefits. Generally, the investment can be recovered in half a year or less. Melt pump assisted plastic extrusion has become increasingly popular in industrial developed countries, but it was rarely used in China due to the development level of plastic industry. With the fierce competition between plastic processing enterprises, people will have to demand high-quality and high-precision extrusion products; More attention is paid to the requirements of material saving and energy saving in the extrusion process and the requirements of high yield and low energy consumption of processing equipment. Adopting melt pump technology as soon as possible is an effective and wise way to meet this requirement. info@battemachinery.com