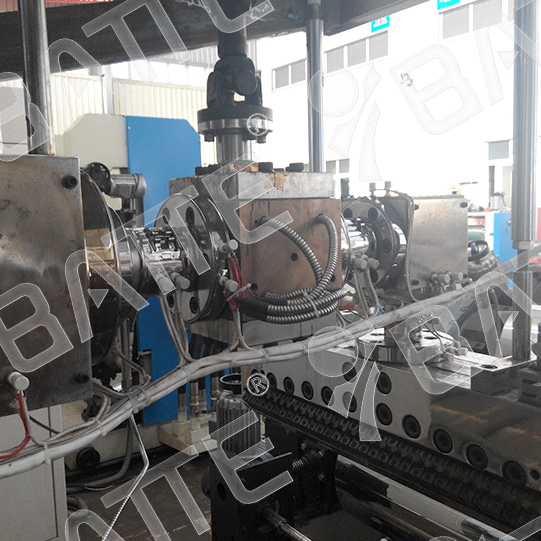

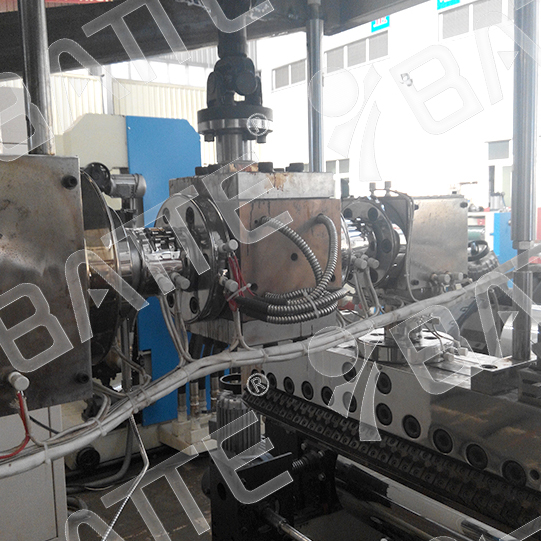

Extruder Metering Melt Pump Start-up Steps Explained

Start-up Procedure

1. Check readiness:

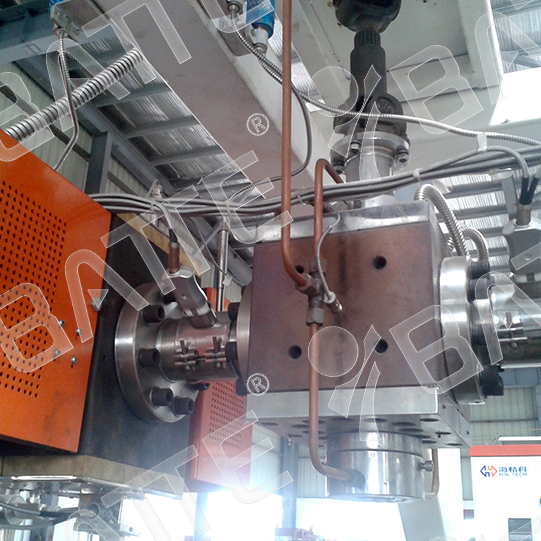

Make sure all connecting parts are tightened and not loose.

Check that the heating systems of the melt pump and extruder are working properly and set the proper temperature.

Make sure that the inlet and outlet pipes of the melt pump are unobstructed.

2. Start the motor:

Before starting the melt pump, start the extruder's motor to ensure that the extruder is running stably.

Then start the motor of the melt pump and gradually increase the speed to the set value.

3. Adjust the flow rate and pressure:

According to the production demand, control the flow rate and pressure by adjusting the speed of the melt pump or the relief valve.

Monitor the running status of the melt pump to ensure stable flow and pressure.

4. Monitoring and recording:

Continuously monitor the melt pump's operating parameters, such as temperature, pressure, flow rate, etc., during start-up.

Record key data for subsequent analysis and optimization.

5. Precautions

SAFETY FIRST: Before starting the pump, make sure all safety precautions are in place to avoid accidents.

Gradual temperature rise: Avoid rapid temperature rise to avoid thermal shock to the melt pump and extruder.

Stabilize the speed: Make sure the speed of the motor and reducer and other transmission parts are stable and reliable to avoid excessive fluctuations affecting the flow rate and pressure.

Regular inspection: Regularly check the wear and tear of key parts such as gears, bearings and seals of the melt pump, and replace the damaged parts in time.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071