Why does the HDPE sheet extruder production line need to install a melt gear pump

The melt pump provides pressure between the extruder and the mold, and can match the parameters of the extruder to provide uniform melt with increased output and strict tolerance requirements. It is generally installed between the outlet of the extruder and the head, and is widely used in polymer extrusion molding such as granulation, film, pipe, plate, and sheet materials. It can also be installed in pipelines to transport high viscosity pure materials. Zhengzhou Bate ZB-B, ZB-C, and ZB-H series melt gear pumps are made of high-temperature alloy steel and powder alloy steel. After a series of hot working and surface treatment such as high-temperature quenching, tempering, quenching and tempering, nitriding, carburizing, carbonitriding and polishing, the product has the characteristics of high temperature resistance, high pressure resistance, high wear resistance and corrosion resistance. The hardness of the product can reach 62-68HRC, which can greatly meet customers' requirements for different working conditions.

Batte melt pump is a positive displacement conveying equipment with high-precision gear clearance and volumetric structural design, making stable and balanced extrusion possible. It has been widely used in production lines such as chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion, etc., and has achieved good results:

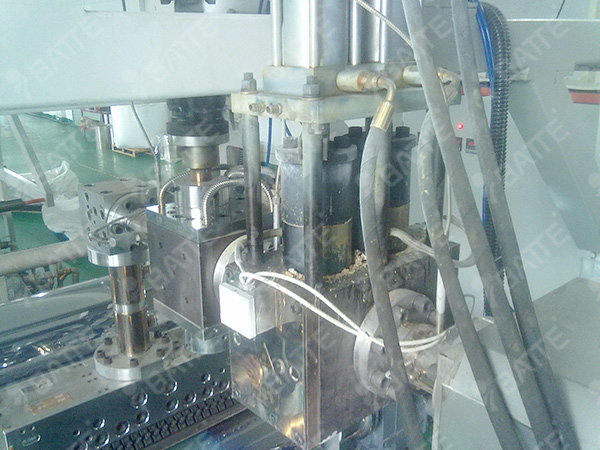

HDPE sheet melt pump Effect One

It can achieve stable extrusion, improve the dimensional accuracy of extruded products, and reduce scrap rates. During the extrusion process, it is difficult to avoid phenomena such as uneven material feeding, fluctuations in barrel and head temperatures, and pulsations in screw speed. The use of a melt gear pump can eliminate feeding errors in the feeding system, significantly reduce fluctuations in upstream process transmission, quickly enter a stable working state, improve the dimensional accuracy of extruded products, and reduce scrap rates.

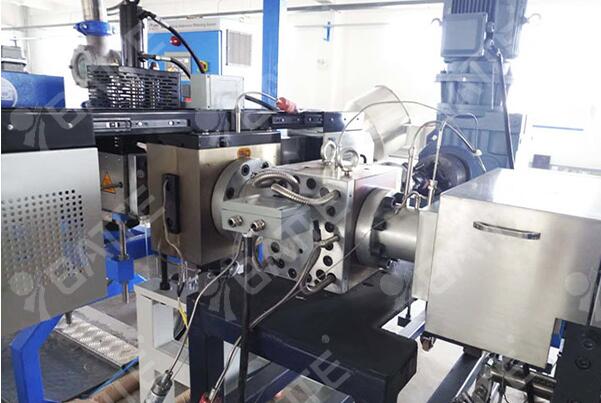

plastic melt pump Effect Two

Increase production, reduce energy consumption, achieve low-temperature extrusion, and extend the lifespan of the machine. Due to the installation of a polymer melt pump in the extruder, the pressure reducing function of the extruder is transferred to the gear pump to complete. The extruder can work under low pressure and low temperature conditions, greatly reducing leakage flow and increasing production. Gear pumps are more effective in establishing head pressure than extruders, and can reduce the back pressure of the extruder, reducing the axial force borne by the screw and extending its service life.

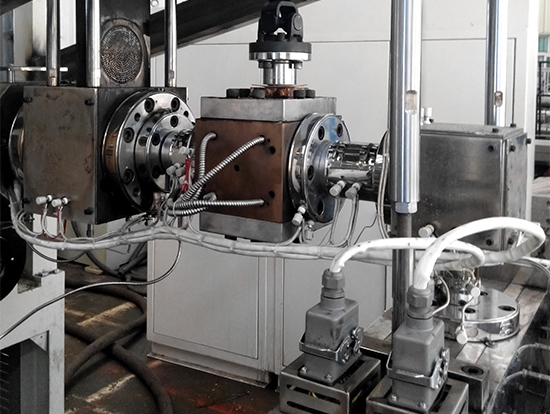

melt pump extrusion Effect Three

It has linear extrusion characteristics, facilitating the coordination of upstream and downstream equipment. Due to the low leakage flow rate of the gear pump, the delivery capacity of the pump is basically linearly related to the speed. After the speed of the gear pump changes, its flow rate can be accurately determined. By determining the synchronous working speed of upstream and downstream equipment and the gear pump, the pressure, temperature and other information collected at the inlet and outlet of the gear pump can be used to achieve online monitoring and feedback control throughout the entire extrusion process.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071