Tips for installing high-temperature melt gear pumps

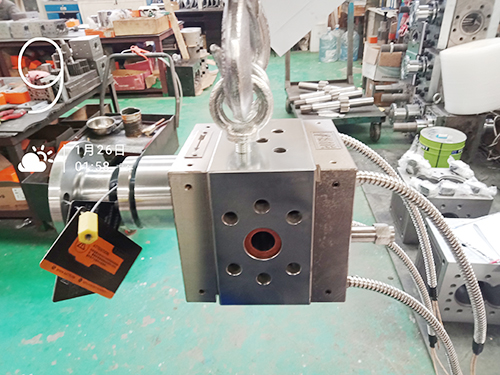

The installation of high-temperature melt gear pumps generally adopts the method of "drive motor+reducer+universal coupling+pump body". The motor adopts variable frequency speed regulation or servo speed regulation, and the speed of the melt gear pump can be adjusted to adjust the required flow rate. For products with high precision requirements, it is recommended to use servo motor speed regulation.

Before installing the high-temperature melt gear pump, use a measuring tool to check and adjust the concentricity between the pump seat and the motor drive shaft. It should be ensured that the high-temperature melt pump shaft rotates in the direction indicated when ordering during operation, otherwise it may cause input shaft fracture and pump body damage.

The base of the high-temperature melt gear pump installation should be flat and have sufficient strength and rigidity. Under the condition of evenly tightening the bolts, it should be ensured that the input shaft can rotate uniformly without jamming. The installation error of the universal coupling should not exceed its allowable deviation value to avoid causing additional force and shortening the service life of the shaft. When tightening the screws during installation, the force should be evenly applied.

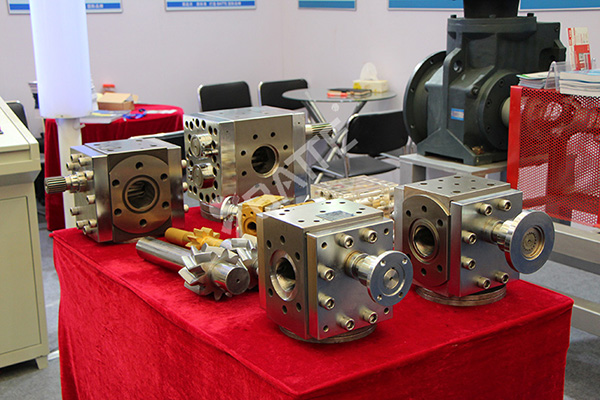

For materials with different properties, BATTE melt pumps can provide different series of melt gear pump products to meet the requirements of different production processes. The melt gear pump products provided by BATTE have the characteristics of precise structure, high accuracy, small pressure and flow pulsation, and long service life; At the same time, we provide full process services such as consultation, design, surveying, maintenance, renovation, and spare parts for the melt gear pump, meeting your requirements in multiple aspects.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071