Application, Materials and Characteristics of High Viscosity and High Precision Gear Metering Melt Pumps

The high precision of high-precision gear metering pumps ensures the accuracy and repeatability of flow, making them particularly suitable for pulsatile precision metering applications in various solvents, strong acids, alkalis, and high viscosity media.

high precision gear metering melt pump

The pump head materials of high-precision gear metering pumps are diverse and optional (high-temperature tool steel, chromium nickel alloy steel, stainless steel), suitable for various acids, alkalis, solvents, various chemical additives metering, transportation, sampling, etc. The flow control of the pump can be achieved by using controllers such as AC and brushless DC motors. It can be applied to high pressure differential, high system pressure, and a wide range of medium viscosity.

high viscosity melt gear pump

The gear metering pump has the following advantages and characteristics:

1. Precision measurement: The measurement accuracy is ± 1%, and the output flow is accurately controlled through speed adjustment.

2. No leakage: Magnetic drive, no extended shaft, no rotating seal design.

3. Stable flow rate, no pulsation: with self priming ability and stable outlet pressure.

4. Capable of dry running: high-precision gears and wear-resistant ceramic shafts.

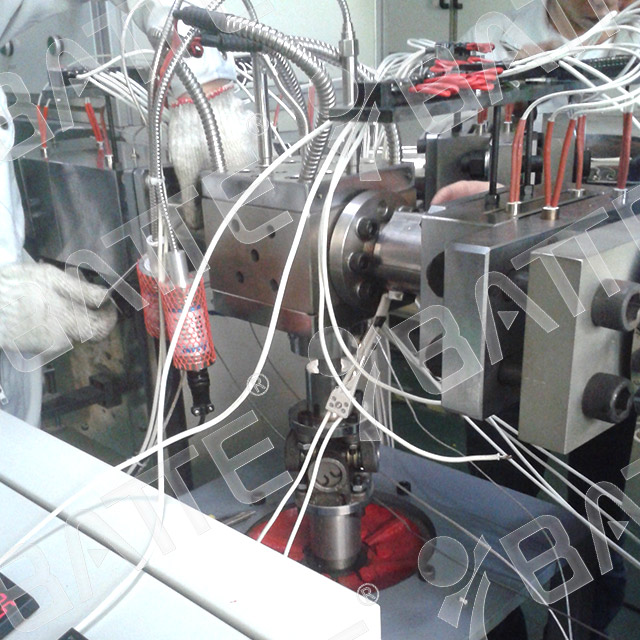

melt pump extrusion

5. Hygienic standard: The liquid passing material meets the hygiene requirements.

6. Pump head material options: 316 stainless steel, Hastelloy, titanium alloy.

7. Optional driving methods: IEC standard motor, ATEX explosion-proof motor, brushless DC motor, servo motor.

plastic melt pump in extruder

Email: info@battemachinery.com

Whatsapp: +86 158 38331071