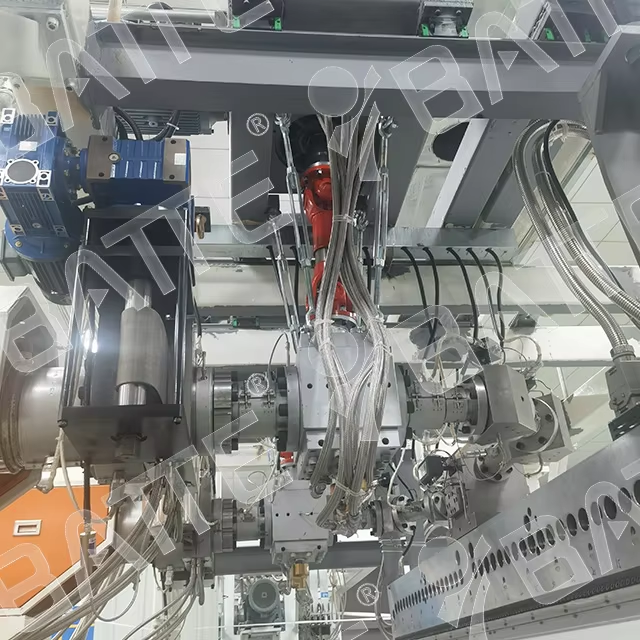

Core Value of Equipping Extruders with Melt Pumps

Adding a melt pump to an extruder is a key optimization solution for enhancing process stability and product quality in plastic processing. The core reasons can be summarized in three points.

Adding a melt pump to an extruder is a key optimization solution for enhancing process stability and product quality in plastic processing. The core reasons can be summarized in three points.

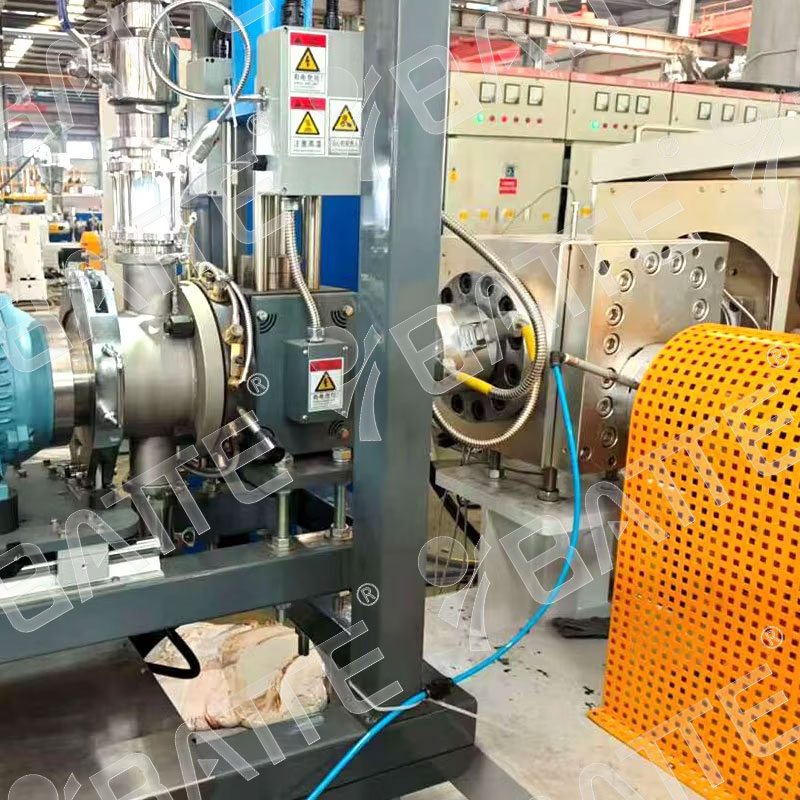

Second, enhanced melt plasticization quality. The pump's shear action refines raw material dispersion, combined with constant temperature control, reduces melt degradation, and minimizes stress and bubble defects in products.

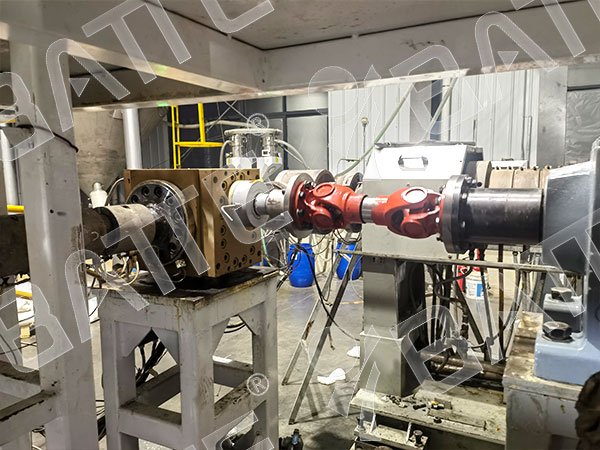

Third, expanded process adaptability. It effectively overcomes pressure losses in scenarios with long flow channels, multiple die heads, or precision extrusion. Simultaneously, it reduces bare-die pressure, lowers equipment energy consumption and wear, and extends the service life of the main unit.

Melt pumps are widely applicable in high-precision extrusion, modified plastic processing, and other scenarios demanding stringent melt delivery stability, serving as core components for achieving efficient production and high-quality output.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071