High-temperature extrusion melt pump application areas and structural composition of the material

Extrusion melt pumps are widely used in the fields of sheet, blown and salivated film, spraying, textile (fibers and nonwovens), EVA, compounding, pelletizing, and biodegradable materials. Under constant pressure, melt pumps have a lower shear stress design, reducing the energy consumption of the extruder, lowering the operating temperature and increasing the output rate.

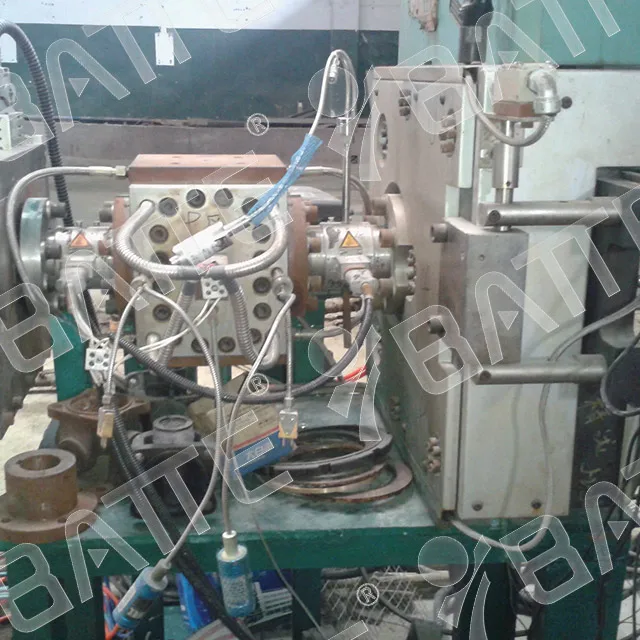

thermoplastic hot melt pumps

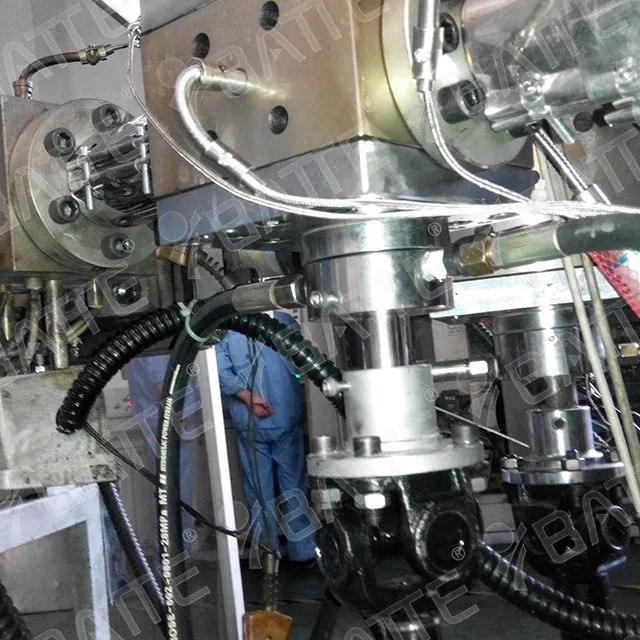

Extruder melt pump structure mainly consists of consists of pump casing, front and rear side cover, gear shaft, slide bearing and shaft seal. For the standard type extruder melt pump, the pump casing and gears are made of nitrided steel, and the bearings are made of tool steel, which has good abrasion resistance, high toughness, cost-effective, and suitable for most of the working conditions with low abrasion. For high abrasion-resistant extrusion melt pumps, the pump casing is made of nitrided steel, and the gears and bearings are made of tool steel, which has high strength and high abrasion resistance and is suitable for abrasive wear conditions. For high corrosion-resistant melt pumps, the pump casing is made of stainless steel, and the gears and bushings are made of tool steel, which have high corrosion resistance and are suitable for highly corrosive working conditions.

melt gear pumps for thermoplastic materials

High-temperature extrusion melt pump features: 1, very small pressure and flow pulsation, can realize the flow of linear output, suitable for precision extrusion system; 2, for different conditions with different structure and material configuration, to better meet the user's individual needs; 3, can be applied to high temperature (350 ° C), high pressure (40MPa), high viscosity (40,000Paos) of the working conditions; 4, Precise structure, high precision and long life.

extrusion melt pump

High temperature extrusion melt pump parameters

Conveying medium viscosity: 0.01~40000Pa-s

Suction pressure: 0~30MPa

Output pressure: 0~40MPa

Permissible differential pressure: 25MPa

Operating temperature: ≤350°C

Heating mode: electric heating

dosing melt pump

Zhengzhou BATTE is a professional melt pump manufacturer, providing a variety of specifications of melt gear pumps for resin, chemical fiber, rubber and other polymer material industries, and various series of melt pump products that can meet all polymer working conditions.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071