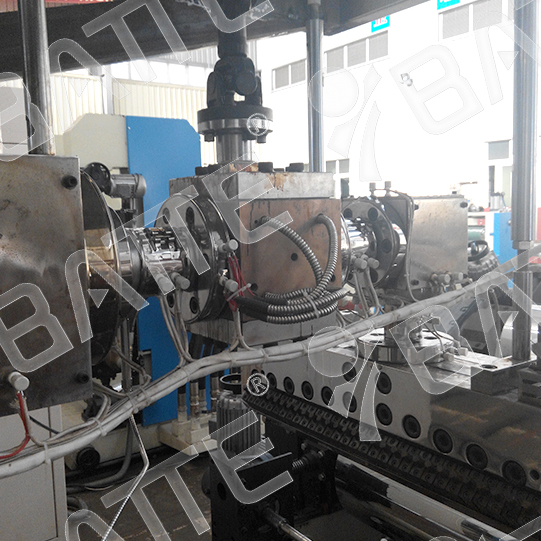

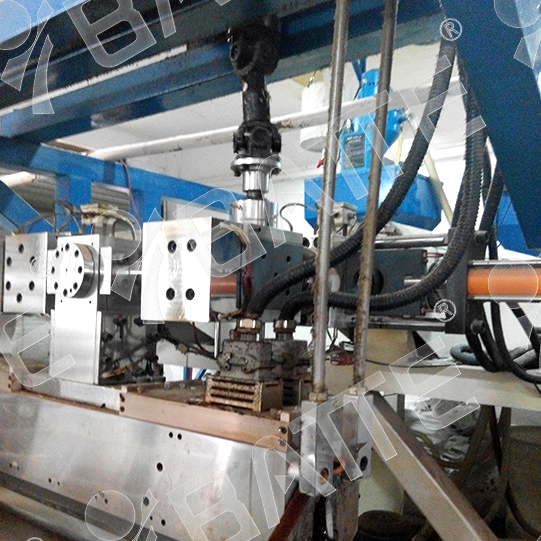

Melt metering pump

Extruder melt metering pumps deliver melt mainly through the change of working volume caused by the mutual meshing of the master and slave gears, with stable output pressure and precise metering capability. Its working principle is similar to that of a volumetric pump, when the gear rotates, the melt is sucked into the tooth groove and discharged with the rotation of the gear, thus realizing the delivery of the melt.

The advantages of melt metering pumps in extruders are mainly reflected in the following aspects: First, it can stabilize the pressure and flow fluctuations in the extrusion process, and improve product quality; Second, it has accurate metering characteristics, and can realize the quantitative delivery of melt; Third, it is a compact structure, good sealing performance, and it is suitable for high temperature, high-viscosity melt delivery; Fourth, it is easy to maintain, and it has a long service life, and it can reduce the production cost.

Melt metering pump extrusion with its stable working principle and many advantages, in the plastics, rubber and other industries has a wide range of applications.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071