What are the common models and sizes of melt metering pumps?

From 0.1cc micro pumps to 4000cc industrial giants, precise displacement to match production needs, zb series to match the melt characteristics, selection needs to be integrated flow, pressure, material compatibility, so that stable operation becomes the starting point of efficiency.

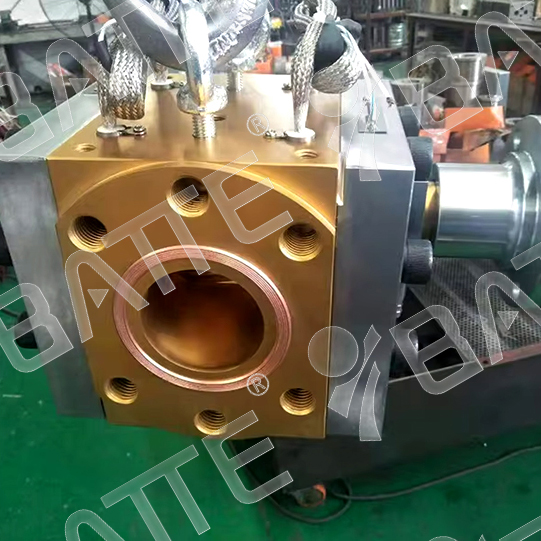

Melt metering pumps are commonly available in a wide range of models and specifications to meet different production needs. The specifications are usually expressed in terms of displacement, i.e., the volume of melt discharged per revolution of the pump, usually in cc (milliliters). Below are some common melt metering pump models and specifications:

Small pumps: such as 0.1cc, 0.5cc, 1cc, 2cc, 5cc, etc. They are suitable for small flow rate and high precision delivery scenarios.

Medium-sized pumps: including 10cc, 20cc, 31.5cc, 50cc, 100cc, 150cc, 200cc, etc., which are widely used in a variety of plastics, rubber and other melt processing industries.

Large-size pumps: such as 315cc, 500cc, 800cc, 1200cc, and even larger sizes such as 2500cc, 3200cc, 4000cc, etc., which are suitable for high-flow and high-pressure conveying needs.

In addition, there are some special specifications of melt metering pumps, such as customized specifications according to the user's actual production needs. Meanwhile, melt metering pumps are also divided into different series according to different working conditions and materials, such as zb-b series and zb-h series, etc., in order to adapt to the characteristics of different melts, such as temperature and viscosity.

In the selection of melt metering pumps, should be based on specific production requirements, melt characteristics and equipment compatibility and other factors for comprehensive consideration, in order to ensure the accuracy of the selection and stable operation of the pump.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071