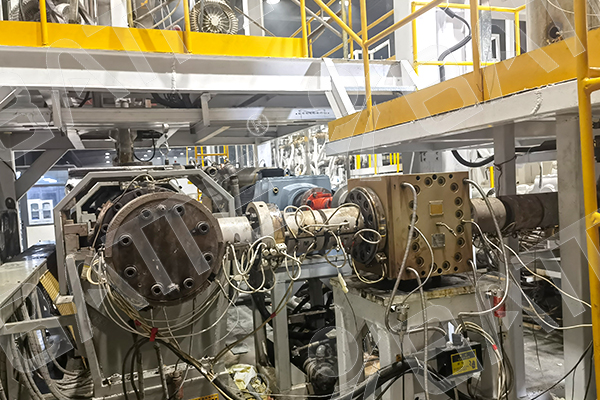

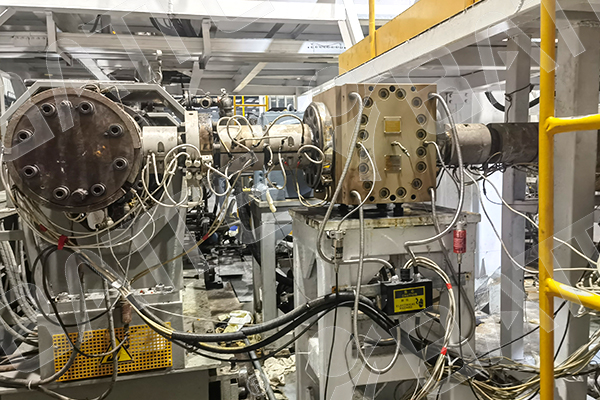

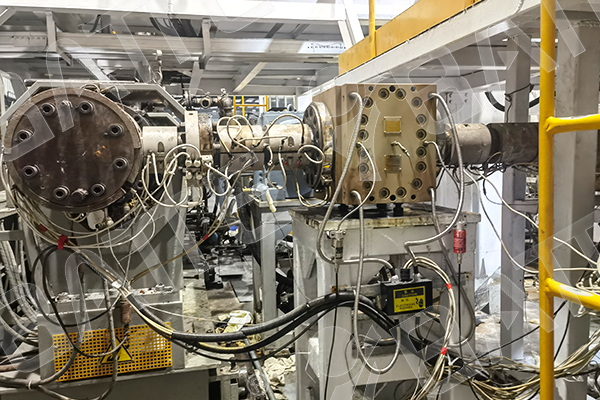

Melt pump for BOPP Film Production Line

The film extrusion melt pump is a critical piece of equipment in plastic film processing, significantly enhancing film quality, production efficiency, and process stability through precise control of melt flow rate and pressure. Below is an analysis from four dimensions: application fields, core functions, typical cases, and trends:

I. Core Application Fields

Packaging Films

Biaxially Oriented Polypropylene (BOPP): Used in food and pharmaceutical packaging, melt pumps ensure uniform film thickness (within ±1.5%), avoiding defects such as "gels" and "shark skin."

Biaxially Oriented Polyester (BOPET): In the production of optical-grade films (e.g., release films, MLCC base films), the pressure-stabilizing function of melt pumps ensures consistent optical performance.

Cast Polypropylene (CPP): Achieves high-speed production (line speed up to 400-500m/min) through melt pumps, enhancing capacity and reducing energy consumption.

Functional Films

Photovoltaic Backsheet Films: Melt pumps precisely control the thickness ratio of each layer in multi-layer co-extrusion, ensuring barrier properties and adhesion strength.

Lithium-Ion Battery Separators: In the production of ultra-thin (≤5μm) separators, the micro-flow regulation capability of melt pumps ensures uniform porosity.

Laser Transfer Films: Through the cooperation of melt pumps and precision dies, nano-level coating thickness control is achieved, enhancing optical effects.

Agricultural and Industrial Films

Agricultural Greenhouse Films: Melt pumps adapt to high-fill formulations (e.g., CaCO₃), reducing material costs and improving mechanical properties.

Geomembranes: In large-scale production lines, melt pumps connected in series with multiple extruders achieve stable extrusion of ultra- wide (≥10m) films.

II. Core Functions and Advantages of Melt Pumps

|

Function |

Technical Implementation |

Application Value |

|

Pressure Stability |

Forced delivery via gear meshing, pressure fluctuation ≤ ±0.5% |

Eliminates film thickness fluctuations, reduces scrap rate (e.g., BOPP CD deviation from ±3% to ±1.5%) |

|

Precise Flow Control |

Displacement accuracy ±0.3%, coupled with closed - loop control |

Achieves high - precision adjustment of film gram weight and width (e.g., lithium battery separator thickness error ≤ ±0.2μm) |

|

Enhanced Process Adaptability |

Handles viscosity range 500 - 3000Pa·s, withstands high temperatures (350°C) and pressures (40MPa) |

Adapts to different formulations (e.g., high - fill, blend modification) and processes (e.g., multi - layer co - extrusion, high - speed stretching) |

|

Energy Optimization |

Reduces extruder back - pressure, decreases screw shear heat, saves 10% - 25% energy |

In a BOPP enterprise with an annual output of 4 million tons, reduces energy consumption per ton by 10% - 15%, saving over 10 million yuan in annual electricity costs for a BOPP enterprise with an annual capacity of 4 million tons |

|

Extended Equipment Lifespan |

Wear - resistant gears (e.g., nitrided steel) and special coatings (e.g., DLC - like diamond - like carbon) |

Extends pump body lifespan from 1 year to 3 - 5 years, shortens maintenance cycle from weekly to monthly |

III. Analysis of Typical Cases

Case 1: BOPP Film Production Line Upgrade

Problem: The original production line had uneven film thickness due to extruder pressure fluctuations, resulting in an 8% scrap rate.

Solution: Introduced a ZB - 180/180 - 3200CC type melt pump, coupled with an online thickness measurement system.

Effect: Film thickness deviation reduced from ±2.5% to ±1.2%, scrap rate dropped to 2%, and production capacity increased by 15%.

Case 2: Micron - Level Control of Lithium - Ion Battery Separators

Problem: Separator thickness needed to be controlled within 5±0.3μm, and traditional equipment could not meet the accuracy requirements.

Solution: Used a customized melt pump with gear clearance accuracy of 0.01mm, coupled with a laser thickness gauge.

Effect: Separator thickness uniformity improved by 40%, porosity consistency reached 98%, and product yield increased from 75% to 92%.

Case 3: High - Fill Formulation for Agricultural Greenhouse Films

Problem: High - fill (30% CaCO₃) led to high extruder back - pressure and poor melt flow.

Solution: Connected the melt pump in series with a single - screw extruder, optimized gear material and clearance.

Effect: Back - pressure reduced by 30%, film tensile strength increased by 20%, and material cost reduced by 12%.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071