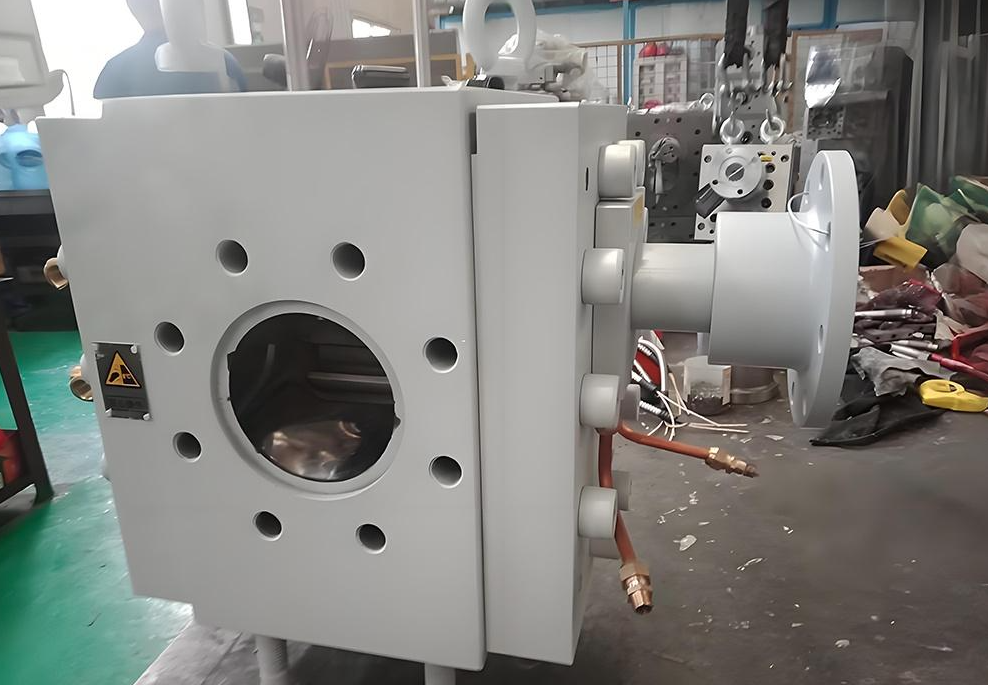

Silicone Tube Extrusion Melt Pump

An in-depth analysis of the advantages of silicone tube extrusion melt pumps highlights their core value in the production process. The following is a detailed examination of their multiple advantages:

1. Stable Melt Pressure for Consistent Production

During silicone tube extrusion, the primary advantage of the melt pump lies in its ability to maintain stable melt pressure. This feature effectively prevents pressure fluctuations during the extrusion process, laying a solid foundation for the stable production of high-quality products like silicone tubes. Stable melt pressure ensures the continuity and uniformity of the extrusion process, thereby enhancing the overall quality of the product.

2. Precise control of melt flow rate to improve product consistency

The melt pump's ability to precisely control melt flow rate is another significant advantage. By accurately regulating the melt flow rate, it ensures the consistency and dimensional accuracy of extruded products. For products like silicone tubing that require strict dimensional control, this advantage is particularly important. It ensures that the produced silicone tubing has more accurate dimensions, meeting the market's demand for high-quality extruded products.

3. Improving melt uniformity to enhance product quality

Melt pumps can also significantly improve melt uniformity. During the extrusion process, melt uniformity is critical to product quality. Through their unique pumping mechanism, melt pumps ensure that the melt is thoroughly mixed and homogenized before extrusion, further enhancing product quality.

4. Reducing extruder load and extending equipment lifespan

The use of melt pumps also helps reduce the load on extruders. By sharing the working pressure of the extruder, melt pumps enable extruders to operate more efficiently, reducing equipment wear and failure rates. This not only extends the equipment's lifespan but also lowers maintenance costs, providing strong support for continuous production.

5. High-temperature resistance, wear resistance, and corrosion resistance, suitable for harsh conditions

The melt pump is made of high-temperature resistant, wear-resistant, and corrosion-resistant materials, enabling it to operate continuously and stably under high-temperature, high-viscosity harsh conditions. This characteristic is particularly important for the production of extruded products such as silicone tubes, as silicone materials themselves have high melting points and viscosities. The melt pump's high-temperature resistance and wear resistance ensure stable operation under harsh conditions, providing a strong guarantee for product production.

6. Comprehensive improvement in production efficiency and product quality

In summary, the multiple advantages of silicone tube extrusion melt pumps collectively enhance the production process, significantly improving production efficiency and product quality. Through stable melt pressure, precise control of melt flow, improved melt uniformity, reduced extruder load, and adaptability to harsh conditions, the melt pump injects powerful momentum into the production of silicone tubes and other extruded products. This gives enterprises a competitive edge in the market and meets the growing demand for high-quality extruded products.

Therefore, the silicone tube extrusion melt pump is undoubtedly an indispensable key piece of equipment in the production process of silicone tubes and other extruded products. Its multiple advantages provide a strong guarantee for improving product quality and production efficiency, injecting new vitality into the development of enterprises.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071