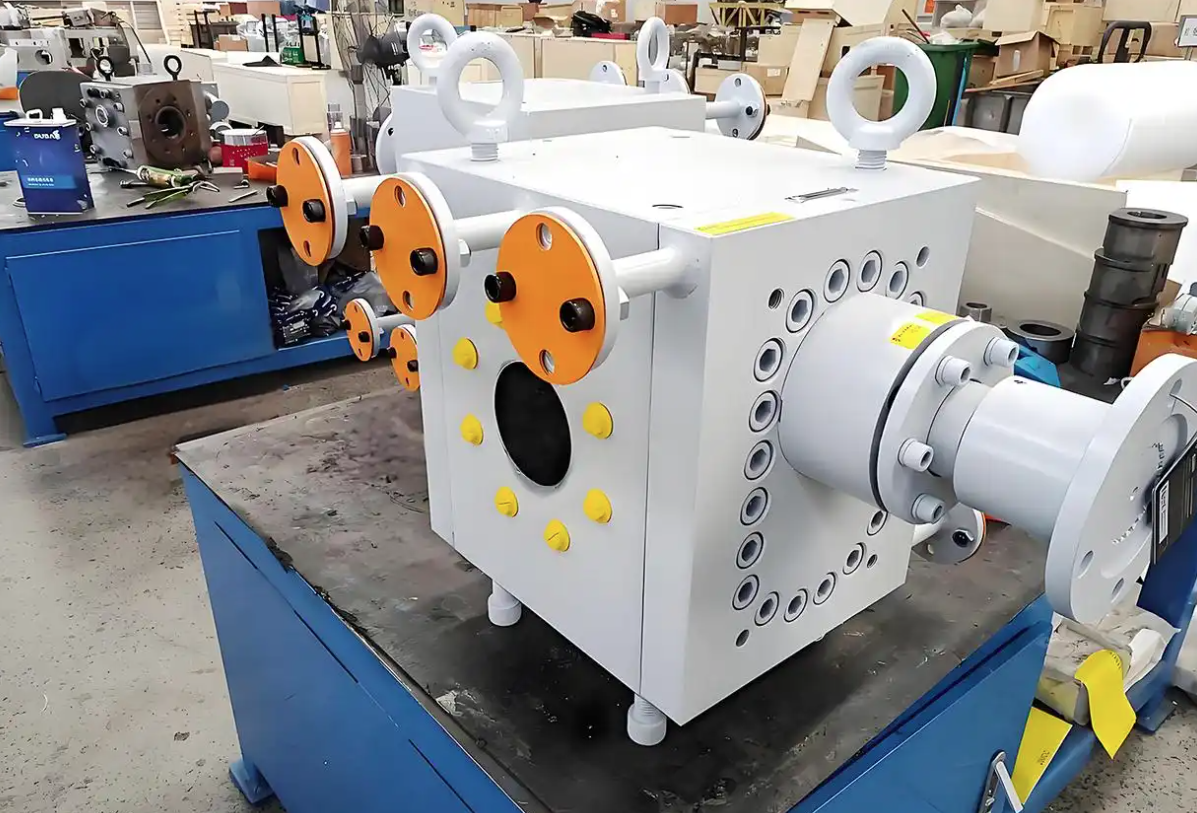

Melt gear pump straight gear and helical gear performance comparison and selection points

In the application of melt gear pumps, spur gears and helical gears are the two most common gear forms. These two gears have their own advantages and disadvantages in performance, this article will be from the transmission smoothness, load-bearing capacity, shear effect, as well as manufacturing and maintenance costs of four dimensions, for you to analyze the performance differences between the two.

First, transmission smoothness and flow stability

Spur gears by virtue of the characteristics of no axial force, so that the bearing load is more simple, giving it the advantage of high structural stability. However, due to the smaller number of teeth meshing at the same time, spur gear pumps in operation will produce a large flow pulsation, which in turn triggers significant vibration and noise, on the product dimensional accuracy.

Helical gears, on the other hand, stand out due to their high overlap mesh, which allows for 2 - 3 pairs of teeth to mesh continuously, resulting in minimal flow pulsations and a smooth, quiet transmission that excels in precision metering scenarios. However, helical gears generate axial forces when rotating, which requires enhanced bearing design.

Second. Bearing capacity and working conditions

Spur gears have a relatively limited bearing capacity and are suitable for conveying low to medium differential pressures (<10MPa) as well as low to medium viscosity materials (<10,000 mPa・s). Under high pressure conditions, spur gears are susceptible to “scraping” due to deflection deformation, i.e., the gears rubbing against the pump chamber.

Helical gear performance is a step up, it can withstand up to 35MPa pressure and greater torque, especially for high viscosity (> 10,000 mPa・s), large flow of complex conditions, in nylon spinning, rubber extrusion and other industrial production plays a key role.

Third, shear effect and material adaptability

The tooth root shear zone of spur gears is more concentrated, and the instantaneous shear rate is higher, and this characteristic may lead to localized overheating degradation of heat-sensitive materials, such as PVC, PLA, etc. The shear effect and material adaptability of spur gears is more concentrated, and the instantaneous shear rate is higher.

Helical gear adopts progressive meshing, effectively reducing the instantaneous shear, but the existence of axial force may exacerbate the shear effect of the tooth side gap, affecting the effect of material conveying.

Fourth, manufacturing and maintenance costs

From the cost point of view, the processing difficulty of spur gears is low, and the manufacturing cost is relatively affordable, and the bearing maintenance is simple and easy to disassemble. And helical gear due to its special tooth structure, processing difficulty and manufacturing costs have increased significantly, routine maintenance work is also more complex.

Melt pump manufacturers concluded that in the application of melt gear pumps and selection process, you need to fully consider the structural characteristics of spur gears and helical gears, and closely combined with the needs of the actual working conditions, in order to select the most appropriate program and configuration.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071