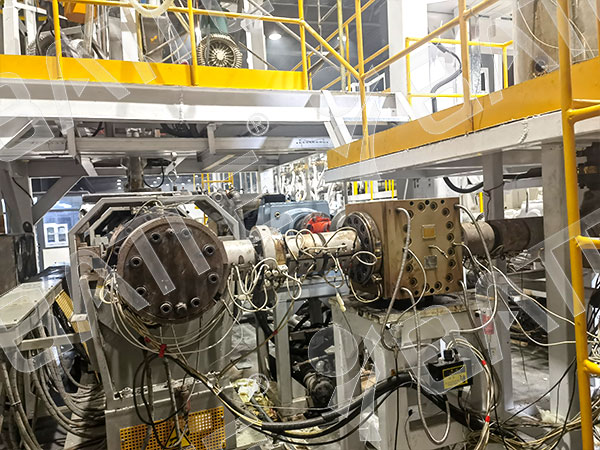

Melt Pump in BOPP Biaxially Oriented Polypropylene Film Production Line

The melt pump plays a crucial role in BOPP biaxially oriented polypropylene film production lines, with its core functions manifested in four key areas: stabilizing melt pressure and flow rate, enhancing film quality, reducing extruder load and energy consumption, and improving production efficiency and material utilization.

Through a precision gear meshing mechanism, the melt pump strictly controls fluctuations in the melt flow rate from the extruder within ±1%, ensuring a constant and precise feed supply for the subsequent biaxial stretching process. This capability eliminates quality defects such as uneven film thickness and longitudinal streaks caused by flow variations at the source, guaranteeing that the final product's thickness tolerance consistently meets the stringent industry standard of ±1%.

The melt pump effectively absorbs pressure surges caused by fluctuations in extruder screw speed and uneven raw material melting, maintaining melt pressure fluctuations within ±1%. This stable pressure environment establishes a more consistent rheological foundation for die extrusion and biaxial stretching processes, enhancing film flatness and optical properties.

Core Functions

Precise pressure and flow control counteracts extruder screw fluctuations, ensuring smoother melt output.

Enhances melt plasticization quality, reducing film defects like crystalline spots and bubbles.

Improves production line adaptability, supporting stable output of high-volume, wide-width films.

Key Application Considerations

Material Selection: Utilize high-temperature and corrosion-resistant alloy materials compatible with PP melt characteristics.

Precision Matching: Pump flow range and pressure control accuracy must align with extruder and stretching machine parameters.

Temperature Control Requirements: Equip with precise temperature control systems to prevent melt cooling crystallization or overheating degradation.

Maintenance Focus: Regularly clean gears and flow channels, inspect seals to prevent melt leakage.

Meeting Diverse Production Demands

Increased Output: The melt pump's stable material delivery reduces production downtime and failure rates, boosting efficiency. Its precise displacement control and stable pressure output also enhance film production volume.

Flexible Adaptability: Through linear flow output and speed adjustment, melt pumps adapt flexibly to production requirements for BOPP films of varying specifications. This enables efficient production line operation and diversified manufacturing, improving material utilization and output.

Simplified Process: Installing a melt pump and extrusion dies for tubes, sheets, or films onto existing single-screw or co-rotating twin-screw pelletizing extruders eliminates the pelletizing step, enabling direct extrusion of finished products. This system is ideal for materials requiring blend modification during extrusion. By streamlining the production process and shortening production cycles, it achieves energy savings and enhanced efficiency.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071