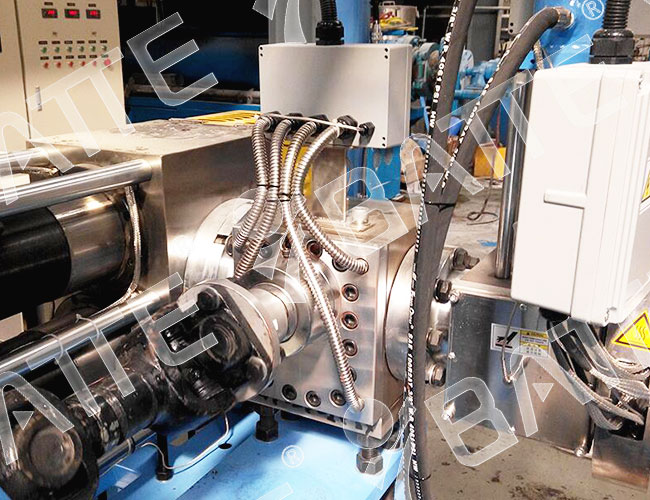

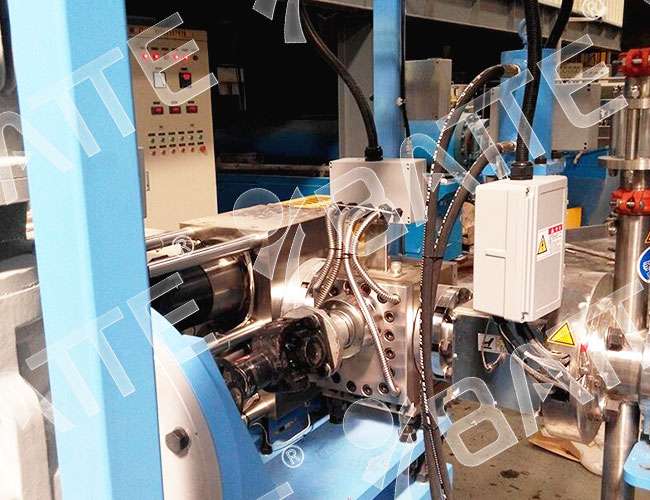

Gear melt pump of plastics pelletizing line

Melt pumps play a critical role in plastic pelletizing extrusion production lines. By precisely controlling melt flow and pressure, they significantly enhance production line stability, efficiency, and product quality.

Melt pumps can process complex materials such as high-viscosity, highly-filled, or recycled plastics. By adjusting melt pump speed and pressure, they adapt to the flow characteristics of different materials, expanding the range of raw materials that can be processed on the production line.

I. Specific Applications in Plastic Pelletizing Production Lines

Enhancing Pelletizing Stability

Particle Size Uniformity: Stable melt flow ensures consistent die extrusion speed, preventing particle size inconsistencies or strand breakage caused by pressure fluctuations.

Cutting Quality: Melt pumps reduce melt pulsation, enabling pelletizers to operate under constant conditions and lowering defect rates such as stick-together pellets and broken pellets.

Enhanced Production Capacity and Reduced Energy Consumption

Optimized Extruder Efficiency: The extruder operates at lower rotational speeds, minimizing mechanical wear and energy consumption. Simultaneously, the melt pump compensates for flow rate, boosting overall production capacity by 10%-30%.

Temperature Control: A stable pressure environment reduces temperature fluctuations caused by shear-induced heat generation in the melt, lowering the load on the cooling system and further improving energy efficiency.

Enhanced Material Adaptability

The melt pump handles complex materials like high-viscosity, highly-filled, or recycled resins. By adjusting pump speed and pressure to match different material flow characteristics, it expands the range of raw materials usable on the production line.

Integrated Automation Control

The melt pump interfaces with PLC or DCS systems for real-time monitoring of pressure, flow, and temperature, enabling closed-loop control and elevating the production line's level of automation.

II. Selection and Configuration Guidelines

Pump Type Selection

Gear Pumps: Suitable for high-precision, low-shear applications (e.g., engineering plastics like PC, PA).

Screw Pump: Suitable for high-viscosity materials containing fillers (e.g., PVC, wood-plastic composites).

Parameter Matching

Flow Rate Range: Select the pump's rated flow rate based on production line capacity, reserving 20%-30% margin to accommodate fluctuations.

Pressure Rating: The pump outlet pressure must exceed die head resistance; typically select models rated at 10-30 MPa.

Material Requirements: Components contacting the melt must use corrosion-resistant and wear-resistant materials (e.g., duplex stainless steel, Hastelloy).

System Integration

Preheating System: The pump body must be equipped with an independent heating ring to ensure uniform melt temperature and prevent localized solidification.

Filtration Device: Install a filter at the pump inlet to prevent impurities from entering the pump chamber, thereby extending service life.

Their application not only improves product quality and output capacity but also reduces energy consumption and maintenance costs, making them particularly suitable for high-value-added, high-precision, or complex material production scenarios.

Proper selection and system integration are key to leveraging the advantages of melt pumps. Customized configurations based on material properties, production capacity requirements, and budget are recommended.

BATTE Melt Pump Factory supports customization. Inquiries are welcome!

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071