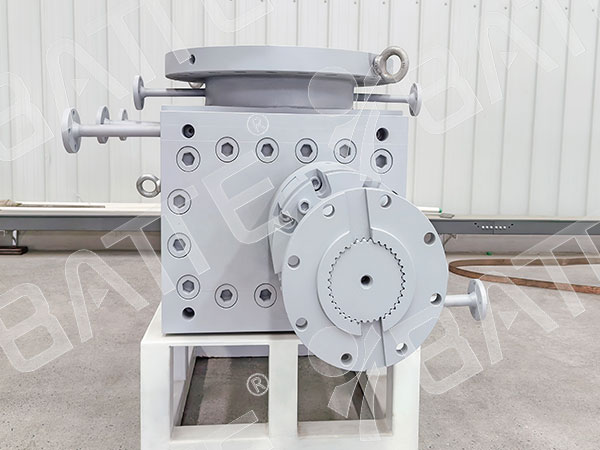

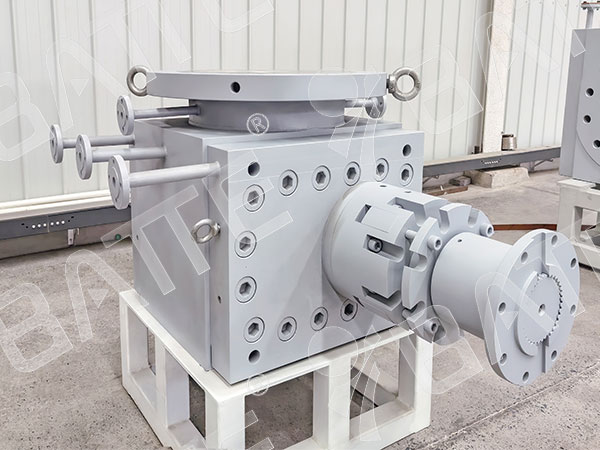

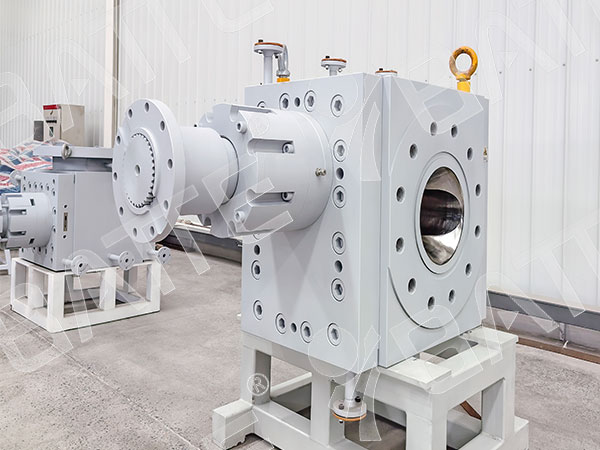

Reactor Kettle Melt Pump

A reactor melt pump is a device used for conveying, pressurizing, and metering high-temperature, high-viscosity polymer melts. Below is a detailed introduction:

Working Principle

Reactor melt pumps are typically gear pumps that convey melt by utilizing the change in working volume created by the meshing of the drive and driven gears. When the gears rotate in the specified direction, the melt enters the feed zone between the gear teeth. As the gears turn, the melt is drawn into the delivery zone from both sides. Upon re-meshing, the melt in the gear pockets is squeezed into the discharge zone and pressurized into the outlet pipeline.

Structural Features

Sealing Structure: Packing seals, mechanical seals, or a combination of both can be selected to effectively prevent leakage.

Material Selection: Pump bodies are available in 304 or 316 stainless steel to accommodate various media, including corrosive substances. Gears can be made from nitrided steel, tool steel, or other materials.

Heating Methods: Some reactor melt pumps feature high thermal efficiency, utilizing electric heating rods or thermal oil heating to maintain melt fluidity.

Performance Advantages

Excellent Self-Priming: Operates under vacuum conditions with a suction pressure down to -0.09 MPa, enabling polymer material transfer and pressurization in vacuum reactions.

Stable Flow: Minimal pressure-flow pulsation enables near-linear flow output for easy control, effectively mitigating pressure fluctuations caused by uneven feeding or temperature variations in extruders.

High Adaptability: Suitable for high-temperature (up to 350°C), medium-to-high pressure (15MPa), and high-viscosity (20,000Pa・s) applications, handling a wide range of medium viscosities.

Application Fields

Primarily used in resin and chemical fiber industries, typically installed as discharge pumps at the bottom of reactors or as booster pumps within pipelines. Additionally suitable for conveying high-viscosity materials without particulate impurities, such as rubber, asphalt, paint, adhesives, dyes, and coatings.

Installation Method

Typically configured as motor + gear reducer + universal joint coupling. The universal joint coupling compensates for thermal expansion displacement between the reactor and piping, ensuring stable operation.

Selection Criteria

Key selection factors include material viscosity, temperature, and particle content. Additionally, pressure and flow requirements must align with process specifications to guarantee stable, efficient operation of the reactor melt pump during production.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071