The Core Function of the Melt Pump in 3D Printing Filament Production

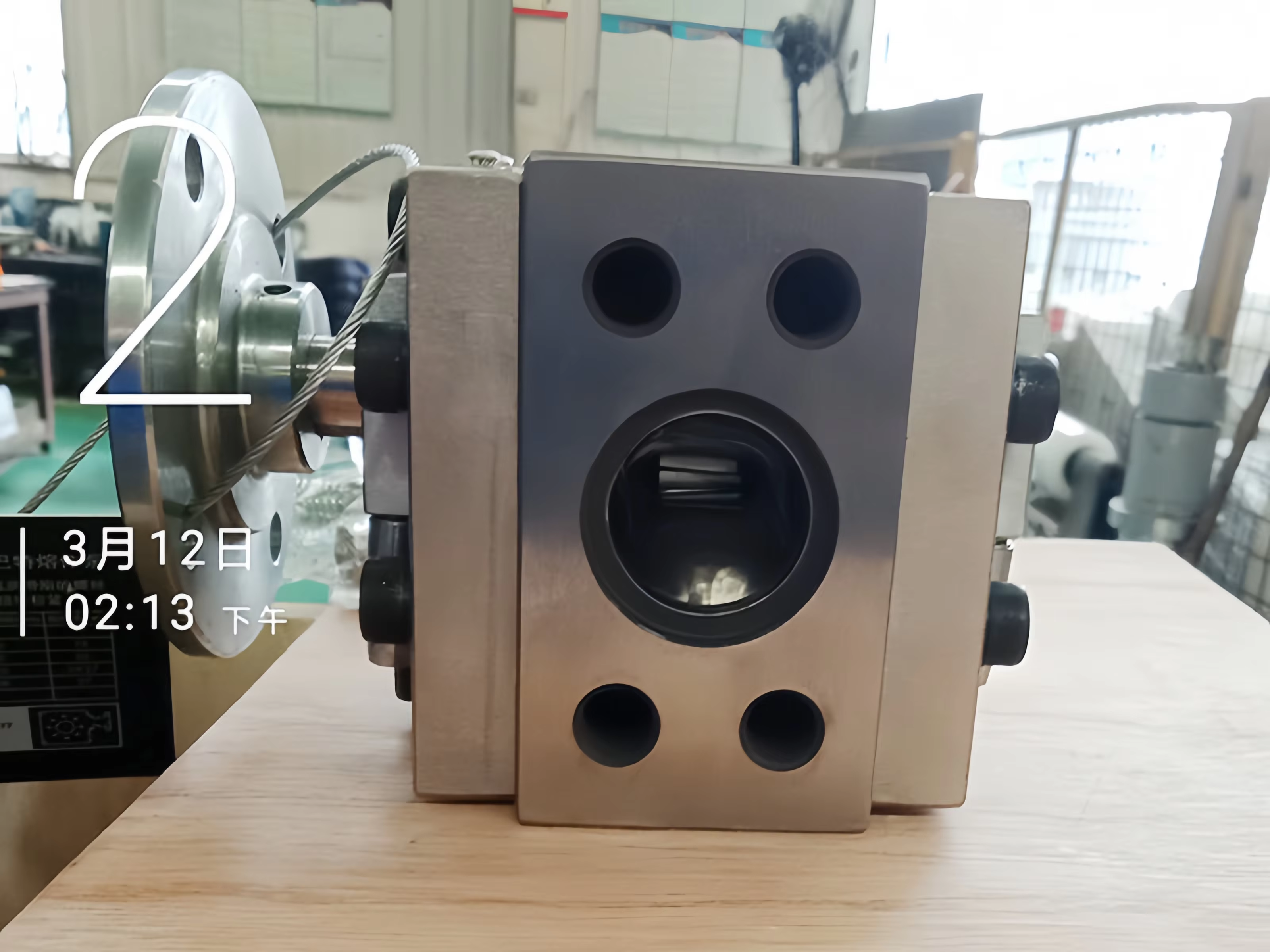

In 3D printing filament extrusion production lines, the melt pump is a critical piece of equipment ensuring filament quality and production stability. Its core functions are threefold: first, precise flow control. Through volumetric pumping via gear meshing, it minimizes fluctuations in melt flow from the extruder, reducing filament diameter tolerances and preventing filament breakage or nozzle blockages during printing.

Second, the internal high-intensity shear eliminates agglomerate bubbles formed during raw material melting, ensuring more uniform melt composition and temperature, thereby enhancing mechanical properties such as tensile strength.

Third, it improves efficiency and reduces consumption by maintaining stable pressure while increasing extrusion speed, minimizing waste caused by parameter fluctuations, reducing extruder load, and extending equipment lifespan—particularly in large-scale production of commonly used materials like PLA and ABS.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071