Technical Analysis of Rubber-Specific Melt Gear Pumps

Rubber-specific melt gear pumps overcome the challenge of conveying high-viscoelastic media. Utilizing high-strength alloy gears and a composite temperature control system, they achieve stable delivery of melts with viscosities up to 40,000 Pa·s, maintaining temperature fluctuations within ±1°C. This enhances production capacity by 20%-30%, providing precise metering support for high-end products like aviation tires.

I. Adaptability to High-Pressure, High-Viscosity Environments

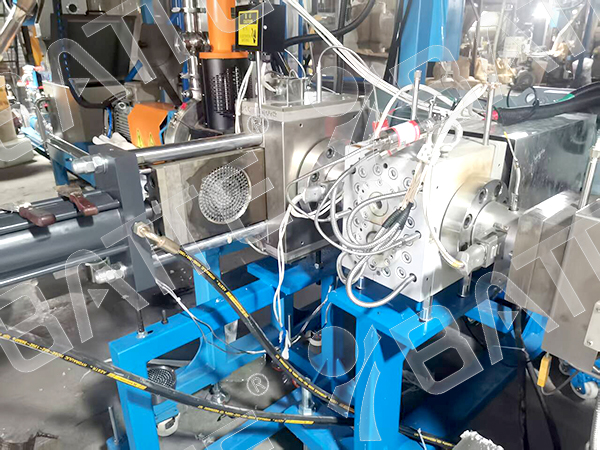

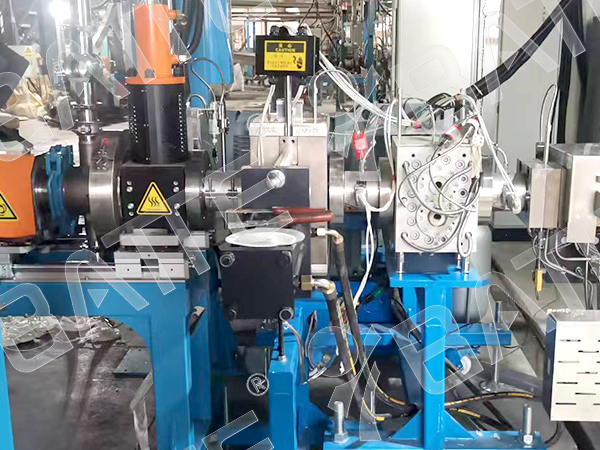

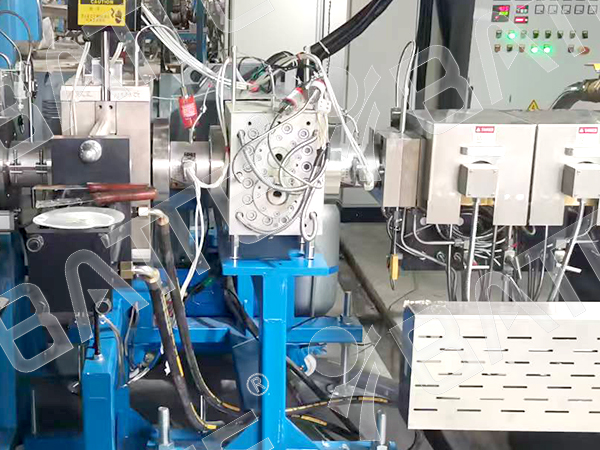

Rubber melt viscosity typically exceeds that of common plastics by tens of times (reaching up to 40,000 Pa·s), while conveying processes endure dynamic pressures ranging from 0 to 35 MPa. By employing high-strength alloy gears and wear-resistant pump body materials (such as nitrided steel and tungsten carbide-coated components), these pumps ensure stable pumping of high-viscosity media. Taking Zhengzhou Bate's products as an example, their developed rubber pumps have achieved continuous conveyance of melt with a viscosity rating of 40,000 Pa·s, meeting the medium transfer demands of high-load operations such as internal mixers and extruders.

II. Precision Temperature Control and Flow Path Design

Compound Temperature Control System:

Rubber gear pumps employ a dual-layer temperature control structure featuring an external jacket + internal flow path. The pump shaft integrates a rotating joint for cooling water circulation and temperature regulation. Combined with electric heating or thermal fluid heating modules, melt temperature fluctuations can be controlled within ±1℃.

Low-Residue Flow Channel Technology:

Streamlined flow channel optimization and dead-zone-free structural design significantly reduce melt retention risks. This is particularly suitable for temperature-sensitive rubber formulations (e.g., those containing vulcanizing agents or heat-sensitive additive systems), effectively preventing premature material degradation or cross-linking.

III. Dynamic Pressure Stabilization and Precision Metering

High-precision gear meshing clearance control and constant-speed drive technology effectively filter pressure fluctuations generated by upstream equipment (e.g., internal mixers, extruders), delivering stable melt pressure input for downstream processes like vulcanization, calendering, and extrusion molding.

IV. Diversified Wear-Resistant Material Solutions

For common rubber melt components like carbon black, fiber fillers, and corrosive additives, key components feature a series of wear-resistant material configurations:

High-hardness nitrided steel gears: Suitable for conventional filler systems, with surface hardness reaching HV1000+;

Tungsten carbide-coated bearings: Designed for high-filler (e.g., ≥50% carbon black) or highly corrosive media, delivering 3-5 times longer wear life;

Through synergistic innovation in material-structure-function, our rubber-specific melt gear pumps resolve industry challenges in high viscoelastic medium transfer—including pressure fluctuations, temperature instability, and component wear. This not only enhances production line stability and efficiency (boosting output by 20%-30%) but also provides critical technical support for quality control in high-end rubber products (e.g., aviation tires, precision seals) via precise metering capabilities. Their modular design and material customization capabilities further expand application scenarios across diverse fields including silicone rubber, fluorocarbon rubber, and thermoplastic elastomers.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071