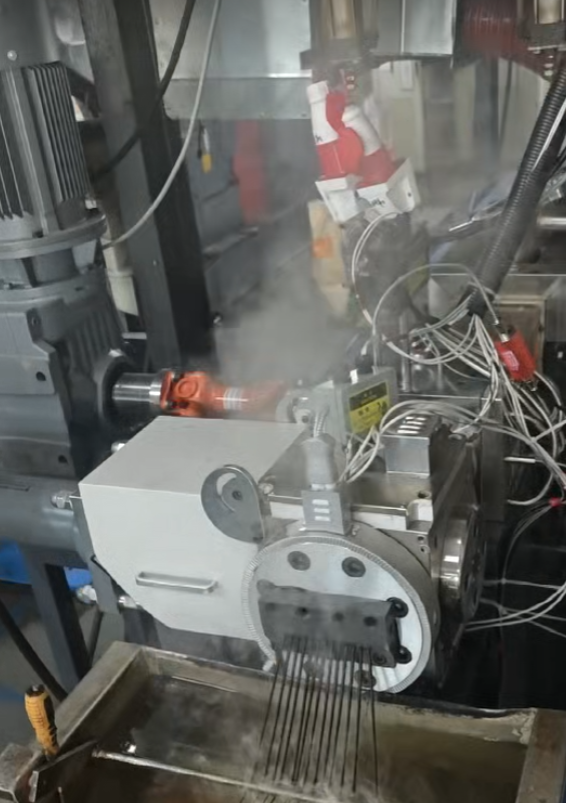

Melt pump in PA (polyamide) pelletizing line

In PA (polyamide) pelletizing production lines, the melt pump serves as the core equipment. Through stable melt delivery, precise metering, and pressure boosting functions, it significantly enhances product quality, production efficiency, and equipment lifespan while reducing energy consumption and scrap rates.

Core Functions of the Melt Pump

Stable Melt Delivery

PA melt exhibits high viscosity and temperature sensitivity, making extruder parameter fluctuations prone to causing output instability. The melt pump employs positive displacement delivery (volume change via gear meshing) to convert inlet pressure fluctuations into stable outlet flow. This ensures the melt enters the die head in a constant state, preventing particle size inconsistencies or agglomeration.

Pump outlet pressure and flow fluctuations can be controlled within an extremely narrow range (e.g., ±1%), guaranteeing pelletization precision.

Precise Metering and Pressure Boosting

The melt pump exhibits a strict linear relationship between flow rate and rotational speed. Adjusting the speed allows precise control of PA melt flow, adapting to diverse formulations and process requirements.

High-pressure output capability (up to 40MPa) ensures smooth melt passage through the die, forming uniform pellets. This is particularly advantageous for high-viscosity PA materials (e.g., PA66).

Specific Advantages for PA Pelletizing Lines

Enhanced Product Quality

Dimensional Tolerance Control: The melt pump minimizes dimensional variations in extruded products, reducing scrap and defect rates. For example, PA pellet size uniformity improves by over 30%, meeting stringent standards for high-end applications (e.g., engineering plastics, fibers).

Thickness Consistency: For PA sheet or film pelletization, the melt pump maintains stable melt pressure, controlling product thickness deviation within ±5%.

Enhanced Production Efficiency

Reduced Screw Load: The melt pump handles pressure build-up, allowing the screw to operate at higher speeds (20%-30% increase) while reducing melt residence time in the barrel. This stabilizes the plasticization process and lowers melt temperature (by approximately 5-10°C), thereby shortening production cycles.

Output Increase: Combining twin-screw extruders with melt pumps boosts PA pellet production by 15%-25% while delivering superior mixing quality.

Reduced Energy Consumption and Costs

Energy Optimization: Melt pumps lower extruder backpressure and reduce axial screw forces, cutting energy consumption per kilogram of processed PA by approximately 20%-25%. For example, a co-rotating twin-screw pelletizing unit paired with a melt pump can achieve energy consumption as low as 0.15-0.2 kWh/kg.

Extended Equipment Lifespan: Reduced screw and barrel wear, along with lower gearbox loads, extend maintenance intervals by over 30%, lowering long-term operational costs.

Adaptation to High-Viscosity and High-Temperature Conditions

PA melt viscosity spans a wide range (1E-3~40,000 Pa·s). Melt pumps employ specialized gear designs (e.g., helical gears, herringbone gears) and high-temperature alloy materials (e.g., corrosion-resistant steel, silicon carbide), enabling stable operation at 350°C and 40 MPa pressure. This accommodates processing requirements for various grades including PA6 and PA66.

As a critical component in PA pelletizing lines, melt pumps enhance product quality, production efficiency, and equipment longevity through stable conveying, precise metering, and pressure boosting—while reducing energy consumption and costs. Their irreplaceable role in processing high-viscosity, high-temperature PA materials makes them the core solution for achieving efficient, stable, and cost-effective pelletization.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071