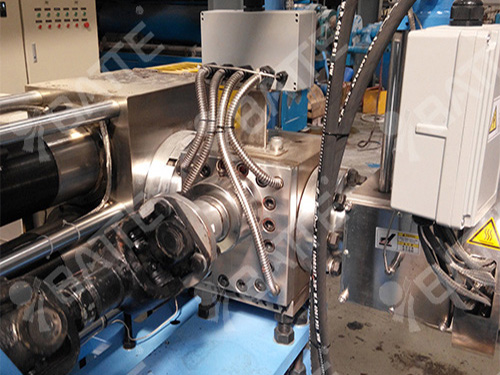

Melt pump and screen changer are used for underwater pelletizing of PP-POE blended elastomer

In the underwater pelletizing process for PP-POE blended elastomers, the rubber melt pump primarily serves to deliver precise, stable pressure and metering. By utilizing gear meshing to achieve stable melt extrusion, it effectively eliminates pressure fluctuations caused by the extruder, ensuring constant melt pressure entering the cutting system and enhancing pellet uniformity.

The melt pump precisely controls melt flow rate to match the speed requirements of underwater pelletizing, while also reducing extruder load and lowering energy consumption. Its specialized design prevents degradation of POE melt caused by excessive shear, safeguarding product performance and production efficiency.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071