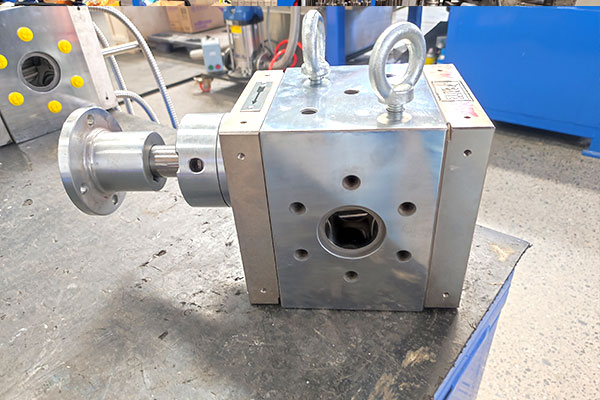

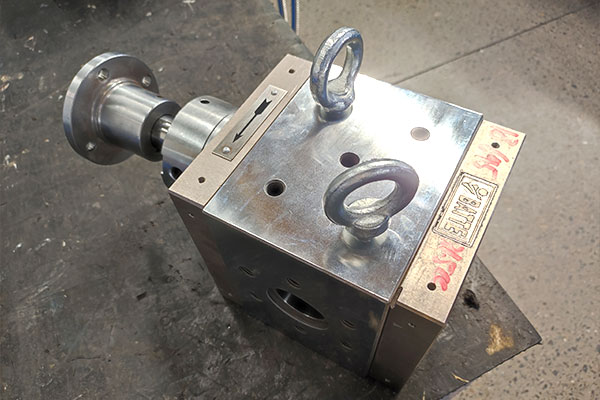

Melt Metering Pump Installation Steps

Before installing the melt metering pump, use measurement tools to check and adjust the concentricity between the pump base and the motor drive shaft. Ensure the melt metering pump shaft rotates in the direction specified at the time of order during operation; otherwise, it may cause input shaft breakage and pump body damage.

The mounting base for the melt metering pump must be level and possess sufficient strength and rigidity. When bolts are uniformly tightened, the pump's input shaft should rotate smoothly without binding.

Installation errors for universal joint couplings must not exceed their permissible deviation values, which should be less than three degrees to prevent additional forces that shorten shaft life. Apply even force when tightening screws during installation.

Prior to operation, the melt metering pump must be heated uniformly, with the temperature not exceeding 120°C per hour. Do not force the pump to start before it reaches operating temperature.

Regardless of manufacturer or model, melt metering pumps must operate at low speed for a period when loading. Only after bearings are fully lubricated should load be applied and working pressure gradually increased.

Once overall operation stabilizes, the pump and entire system may be progressively adjusted to normal process speed and pressure.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071