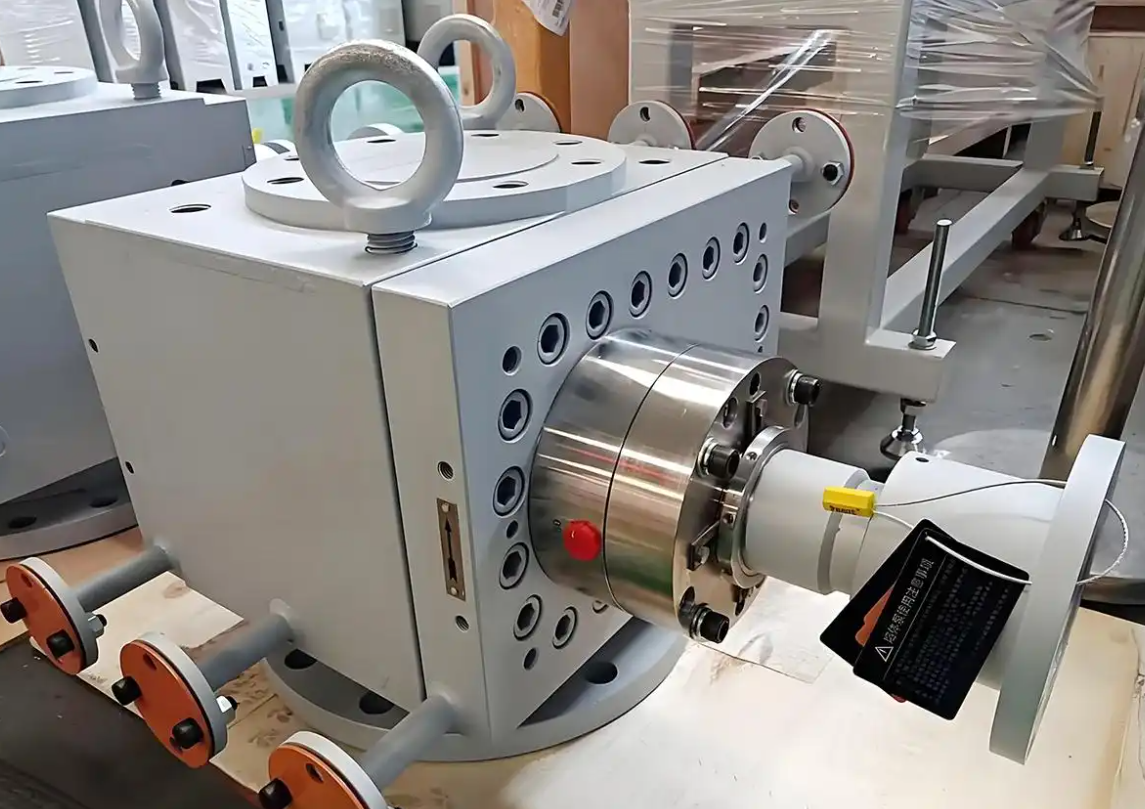

Vacuum Reactor Kettle Gear Pump

The vacuum reactor gear pump serves as critical equipment for conveying high-temperature, high-viscosity polymer melts. It finds extensive application in industries demanding high output pressure, such as resin and chemical fiber production. Typically installed at the reactor bottom as a discharge pump, its large-diameter inlet design accommodates high-flow feed requirements from the reactor base. Featuring excellent self-priming capability, it reliably performs polymer material transfer and pressurization under vacuum reaction conditions.

The pump's performance parameters cover a broad range: it can handle media with viscosities from 0.0001 to 40,000 Pa·s, with suction pressures ranging from vacuum to 4 MPa. Output pressure can reach 0–35 MPa (with differential pressure controlled within 25 MPa).

Operating temperature: up to 350°C. Heating methods are flexible and diverse, including thermal fluid jackets, flow channel heating, and electric heating.

In installation configuration, it adopts a combination of motor + reducer + universal coupling. The universal coupling effectively compensates for displacement caused by thermal expansion of the reactor and piping, ensuring long-term stable operation of the entire system. As a positive displacement forced-flow pump, it achieves near-linear flow output by adjusting speed via variable frequency drive, precisely meeting process flow control requirements.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071